Introduction to Chain plate iron core annealing furnace, how much is the price of the Forging furnace?

Chain plate iron core annealing furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

1、Brief introduction of Chain plate iron core annealing furnace

Chain plate iron core annealing furnaceIt is a forging heating device using gas as fuel.,be loved by our customers.。

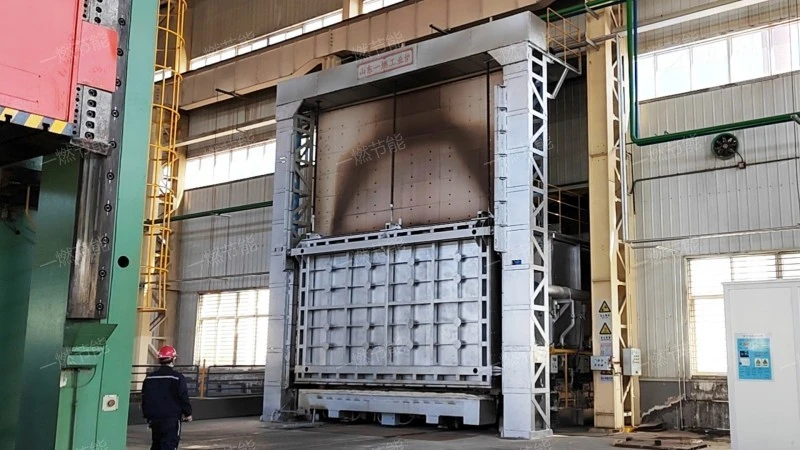

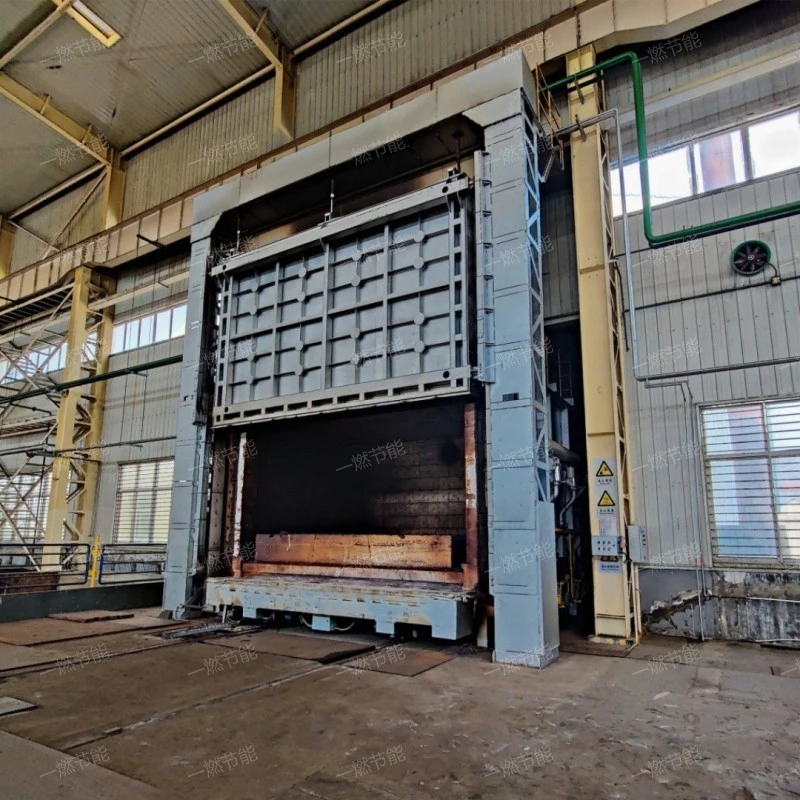

Chain plate iron core annealing furnace

2、Chain plate iron core annealing furnace use

The purpose of Chain plate iron core annealing furnace is introduced as follows:

- Metal forging heating

- Metal melting and casting

- Metal heat treatment

- Metal tempering

- Metal forging heating

The Chain plate iron core annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Although it is mainly used for forging heating, some types of Chain plate iron core annealing furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Chain plate iron core annealing furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Chain plate iron core annealing furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Chain plate iron core annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Chain plate iron core annealing furnace

3、Structural advantages of Chain plate iron core annealing furnace

The Chain plate iron core annealing furnace has the following structure

- Radiation chamber

- combustor

- convection chamber

- ventilation system

- Waste heat recovery system

The heat load of the main place for Chain plate iron core annealing furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Chain plate iron core annealing furnace

4、Chain plate iron core annealing furnace real beat

Chain plate iron core annealing furnace HD factory map, all-round shooting, for our customers to visit.。

Chain plate iron core annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Chain plate iron core annealing furnace introduction video

Speak directly with facts on the spot。

Chain plate iron core annealing furnace

As you can see from the live video.,One-combustion energy saving it has the functions of Forging heating, heat treatment, temper, Casting heating and heat treatment。

6、Chain plate iron core annealing furnace quotation

The Chain plate iron core annealing furnace price is introduced as follows:

- Cost input

- After-sales service level

- product configuration

- type of operation

- product function

The manufacturer has a fixed raw material supplier, so that the raw material price given by the raw material supplier to the manufacturer will be lower, the raw material cost invested by the manufacturer will be reduced, and the price of the Chain plate iron core annealing furnace will also be reduced.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Chain plate iron core annealing furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Chain plate iron core annealing furnace price can meet the purchasing needs of customers.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Chain plate iron core annealing furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Chain plate iron core annealing furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Chain plate iron core annealing furnace

Chain plate iron core annealing furnaceat the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,it has been widely used in material, automobile, aerospace, machinery, heat treatment and other industries。

Related recommendation

-

Introduction to Oxidation reduction flue gas denitrification, how much is the price of the SCR flue gas denitrification?

2025-5-27 -

Introduction to Deep well hot-dip galvanizing furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Step by step quenching furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Quenching well type quenching furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Resistance heating mold shell baking furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

2025-5-27 -

What is a Annealing electric heating furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

2025-5-27 -

What is a Positive pressure heating furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Three-stage walking furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to High temperature continuous quenching heat treatment furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Gas storage through furnace, Forging furnace advantages, characteristics and principles

2025-5-27