Introduction to Chain type iron core annealing furnace, how much is the price of the heating furnace?

Chain type iron core annealing furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,it has been widely used in aerospace, machinery, Machinery manufacturing, shipping, light industry and other industries,multifunctional, with functions such as hardening and tempering, temper, anneal, temper and Forging heating,the main features are Easy to maintain, energy-efficient, energy saving and environmental protection, Strong adaptability and energy-efficient。The following is to introduce the Chain type iron core annealing furnace:

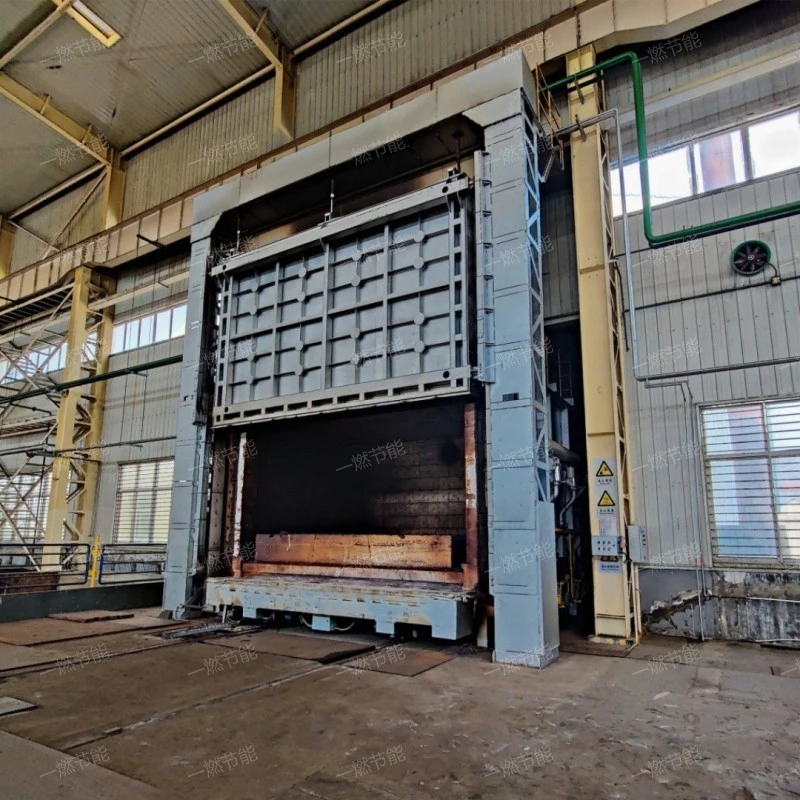

1、Brief introduction of Chain type iron core annealing furnace

Chain type iron core annealing furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,generally, it is composed of ventilation system, ventilation system, recovery of waste heat, combustor, convection chamber and other major components,the product looks beautiful.,It is a product series that integrates Metal heat treatment, Improve production efficiency, Metal melting and casting, Metal melting and casting and Energy conservation and environmental protection,has been favored by more and more customers.。

Chain type iron core annealing furnace

2、Chain type iron core annealing furnace structure

The Chain type iron core annealing furnace structure is introduced as follows:

- furnace chamber

- combustor

- ventilation system

- convection chamber

- Waste heat recovery system

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Chain type iron core annealing furnace

3、Chain type iron core annealing furnace function

Chain type iron core annealing furnaceit has the functions of anneal, Casting heating, normalizing, heat treatment and hardening and tempering,It is an efficient, energy-saving and environment-friendly metal heating device.,it is mainly composed of Radiation chamber, ventilation system, combustor, furnace chamber and ventilation system,Chain type iron core annealing furnaceThe overall structural design is relatively simple and compact.,super quality and competitive price。

Chain type iron core annealing furnace

4、Chain type iron core annealing furnace video detail

Speak directly with facts on the spot。

Chain type iron core annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd Mainly used forMetal heat treatment,Metal tempering,Improve production efficiency,Metal forging heating andMetal heat treatment。

5、How much is the Chain type iron core annealing furnace?

The Chain type iron core annealing furnace price is introduced as follows:

- Manufacturer's strength

- market demand

- Brand strength

- Model size

- After-sales service level

At present, there are many manufacturers of products on the market, some of which belong to direct selling manufacturers and some belong to middlemen. Direct selling manufacturers will cost less than middlemen, so the quotation for products will be lower. Therefore, it is recommended that customers buy products from direct selling manufacturers of Chain type iron core annealing furnace. In addition, even direct selling manufacturers have different capital status, strength level and technology, and the quotation for Chain type iron core annealing furnace will be different.

When the market demand for Chain type iron core annealing furnace is relatively high, manufacturers will raise the price in order to get more profits. On the contrary, when the market demand for this product is low, manufacturers will lower the price in order to sell the remaining products as soon as possible.

At present, there are various brands of Chain type iron core annealing furnace in Jinan, Shandong province. The performance, quality and after-sales of products under different brands are different, and the prices of Chain type iron core annealing furnace are different.

Customer needs are different, so the required product models will be different. Different product models and different performances will naturally lead to different Chain type iron core annealing furnace prices.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Chain type iron core annealing furnace price and service can meet the actual needs of customers.

Chain type iron core annealing furnace

6、One-combustion energy saving after-sales service

Our company can provide you with all-round, high-quality and professional services, especially in after-sales service, which has been unanimously recognized and favored by our customers.。

One-combustion energy saving

Chain type iron core annealing furnacethe main structure includes ventilation system, Radiation chamber, ventilation system, furnace chamber, recovery of waste heat and so on,is a popular Chain type iron core annealing furnace,Strong adaptability,Easy to maintain,energy saving and environmental protection,Stable and reliable,Easy to control。

Related recommendation

-

Introduction to Composite heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Natural gas storage chain grate furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

What is a Regenerative natural gas roller furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

天然气连续加热炉

2023-03-12 -

Introduction to Deep well annealing furnace and heating furnace structure principle

2025-5-27 -

Introduction to Fully automatic step heating furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Resistance heating forging furnace and Trolley electric heating furnace advantages and features

2025-5-27 -

Introduction to Steel plant solid furnace flue gas denitrification system, how much is the price of the SCR denitration system?

2025-5-27 -

Introduction to Large scale tubular roaster, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Heat treatment tube furnace, introduction to Forging furnace advantages and characteristics

2025-5-27