What is a High temperature bright well quenching furnace? Introduction to the Working Principle of heating furnace

High temperature bright well quenching furnaceIt is a forging heating device using gas as fuel.,is carefully developed by One-combustion energy saving combined with advanced technology。

1、Brief introduction of High temperature bright well quenching furnace

High temperature bright well quenching furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it is widely used inmetallurgy,machinery,automobile,electron,heat treatment and other industries,the product looks beautiful.,be loved by our customers.。

High temperature bright well quenching furnace

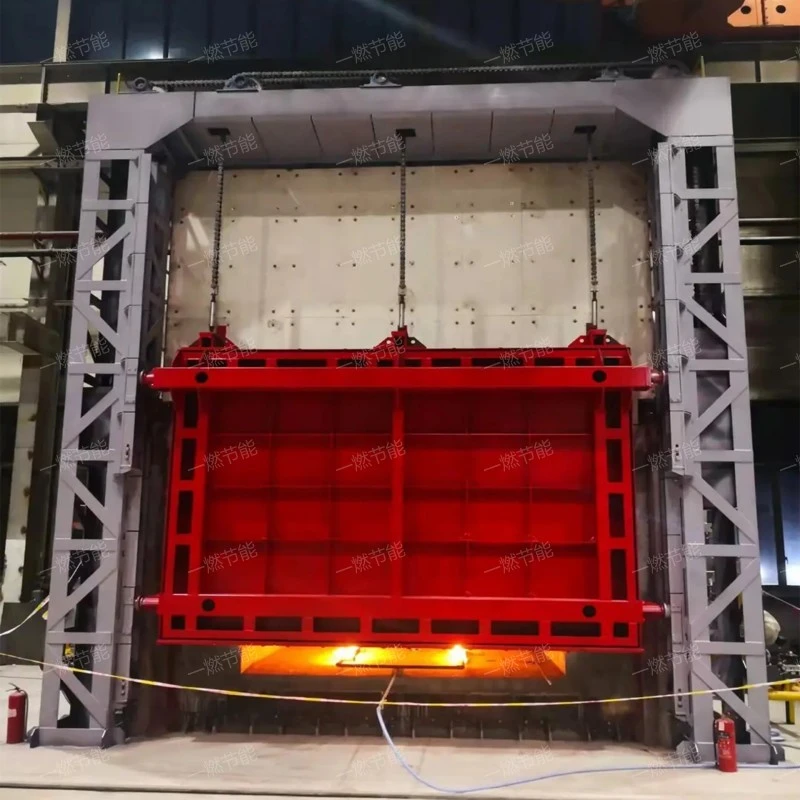

2、High temperature bright well quenching furnace HD real shot

On-site aerial photography of High temperature bright well quenching furnace。

High temperature bright well quenching furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the main features are Strong adaptability, energy-efficient, Stable and reliable, energy saving and environmental protection and Easy to maintain。

3、High temperature bright well quenching furnace function

High temperature bright well quenching furnaceit has the functions of Forging heating, quench, Casting heating, heat treatment and normalizing,Easy to control,Strong adaptability,energy-efficient,Easy to maintain,energy saving and environmental protection,widely used in aerospace, light industry, Machinery manufacturing, petroleum, petroleum and other fields,The price is relatively low.。

High temperature bright well quenching furnace

4、High temperature bright well quenching furnace application

High temperature bright well quenching furnaces have the following purposes.

- Metal tempering

- Metal forging heating

- Improve production efficiency

- Metal heat treatment

- Metal melting and casting

By properly heating and cooling the metal material, the High temperature bright well quenching furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The High temperature bright well quenching furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The High temperature bright well quenching furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

In addition to forging heating, High temperature bright well quenching furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Although it is mainly used for forging heating, some types of High temperature bright well quenching furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

High temperature bright well quenching furnace

5、High temperature bright well quenching furnace display

Exquisite design, advanced technology and complete sizes and models are available for customers to choose at will.。

High temperature bright well quenching furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

High temperature bright well quenching furnaceWidely used inMetal melting and casting,Metal forging heating,Metal tempering,Energy conservation and environmental protection,Improve production efficiency and so on,multifunctional, with functions such as hardening and tempering, Forging heating, anneal, quench and heat treatment。

Related recommendation

-

Introduction to Double bridge trolley resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

What is a Automatic lifting electric heating furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

2025-5-27 -

What is a Natural gas tube quenching furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to High temperature annealing furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Large roller bottom heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

室式电阻炉

2023-03-13 -

Introduction to Regenerative burner box type heating furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Energy saving and environmentally friendly chain grate furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Industrial tubular heating furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Double door well quenching furnace, introduction to Forging furnace advantages and characteristics

2025-5-27