Introduction to Heat treatment resistance furnace, introduction to Trolley resistance heating furnace advantages and characteristics

Heat treatment resistance furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,it is widely used inmachinery,New material development,fireproofing,metallurgy,pottery and porcelain and other industries,is a common Heat treatment resistance furnace,at the start of the operation,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,the main structure includes thermal insulation (material), furnace shell, heating element, Temperature control system and fire door。

1、Brief introduction of Heat treatment resistance furnace

Heat treatment resistance furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,is carefully developed by One-combustion energy saving combined with advanced technology。

Heat treatment resistance furnace

2、Structural characteristics of Heat treatment resistance furnace

The Heat treatment resistance furnace structure is introduced as follows:

- eye split

- fire door

- furnace shell

- heating element

- furnace body

It is arranged on the furnace body and used to observe the heating situation in the furnace.

The furnace Heat treatment resistance furnace is the passage for operators to enter and leave the furnace, and it also plays a certain sealing role. It can effectively prevent the heat in the furnace from leaking out and the cold air from outside from entering, and ensure the stability of the temperature in the furnace.

The furnace shell is usually made of steel plate for protection.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

Heat treatment resistance furnace

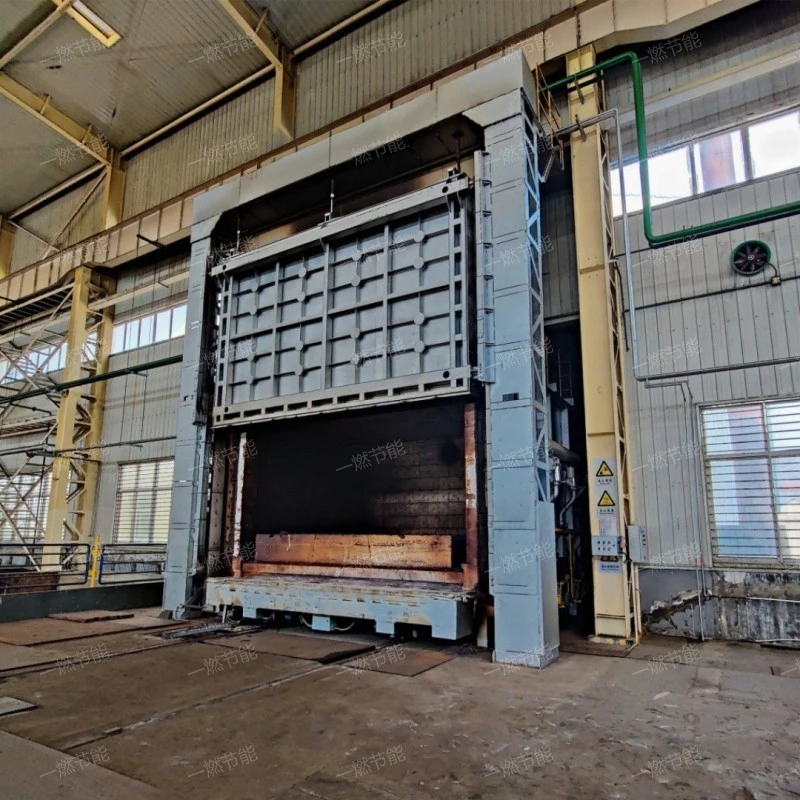

3、Heat treatment resistance furnace HD real shot

On-site aerial photography of Heat treatment resistance furnace。

Heat treatment resistance furnace

As you can see from the live video.,One-combustion energy saving is a kind of high quality and low price Heat treatment resistance furnace。

4、Heat treatment resistance furnace HD real shot

One-combustion energy saving Heat treatment resistance furnace manufacturers, a variety of series of Heat treatment resistance furnace with high-definition pictures at a glance, showing the product style, for the majority of users to choose at will.。

Heat treatment resistance furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Heat treatment resistance furnace performance advantage

The advantages of Heat treatment resistance furnace are as follows:

- easy to operate

- Low maintenance cost

- Pollution-free discharge

- High security

- Strong customization

The operation of the Heat treatment resistance furnace is relatively simple, and it is easy to realize automatic control, which is helpful to improve production efficiency.

The structure of the Heat treatment resistance furnace is relatively simple, and it is convenient to maintain, and the failure rate is relatively low, which helps to reduce the maintenance cost.

The Heat treatment resistance furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.

The Heat treatment resistance furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.

The Heat treatment resistance furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.

Heat treatment resistance furnace

6、Heat treatment resistance furnace quotation

The Heat treatment resistance furnace price is introduced as follows:

- Low cost of raw materials

- select a qualified person

- After-sales service level

- market supply and demand

- regional difference

Product manufacturers are different, and the cost spent by each manufacturer in producing products is definitely different. The higher the cost of producing products, the higher the price of products set by manufacturers. On the contrary, the Heat treatment resistance furnace price is low.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Heat treatment resistance furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Heat treatment resistance furnace price can meet the purchasing needs of customers.

The market demand has a certain impact on the price of Heat treatment resistance furnace. When there are many customers who need Heat treatment resistance furnace in the market, there will be a phenomenon that demand exceeds supply, and then the price of Heat treatment resistance furnace will become higher. On the contrary, when there are very few customers who need Heat treatment resistance furnace, there will be a phenomenon of oversupply, and the price of Heat treatment resistance furnace will be reduced.

Different provinces and regions have different consumption levels, different market positioning and different prices.

Heat treatment resistance furnace

Heat treatment resistance furnaceat work,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,the product looks atmospheric.。

Related recommendation

-

What is a Denitrification system for steel plant heating furnace? Introduction to the principle of SCR flue gas denitrification structure

2025-5-27 -

Introduction to Multiple electric resistance heating furnaces and Trolley resistance heating furnace structure principle

2025-5-27 -

Introduction to Walking ring heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to Continuous bright quenching heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Tempered well type heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Roller bottom guide rail annealing furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Multi tube continuous annealing furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

井式台车加热炉

2023-09-08 -

回转台车锻造炉

2023-09-03 -

Introduction to Roller type quenching heating furnace, how much is the price of the Forging furnace?

2025-5-27