Introduction to Aluminum alloy heat treatment electric heating furnace, how much is the price of the Trolley electric furnace?

Aluminum alloy heat treatment electric heating furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,Widely used inquench,normalizing,Metal heat treatment heating,Melting of low melting point metal,Roasting and annealing of glass ceramics and so on,at runtime,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,is a Aluminum alloy heat treatment electric heating furnace newly developed by One-combustion energy saving。The following is to introduce the Aluminum alloy heat treatment electric heating furnace:

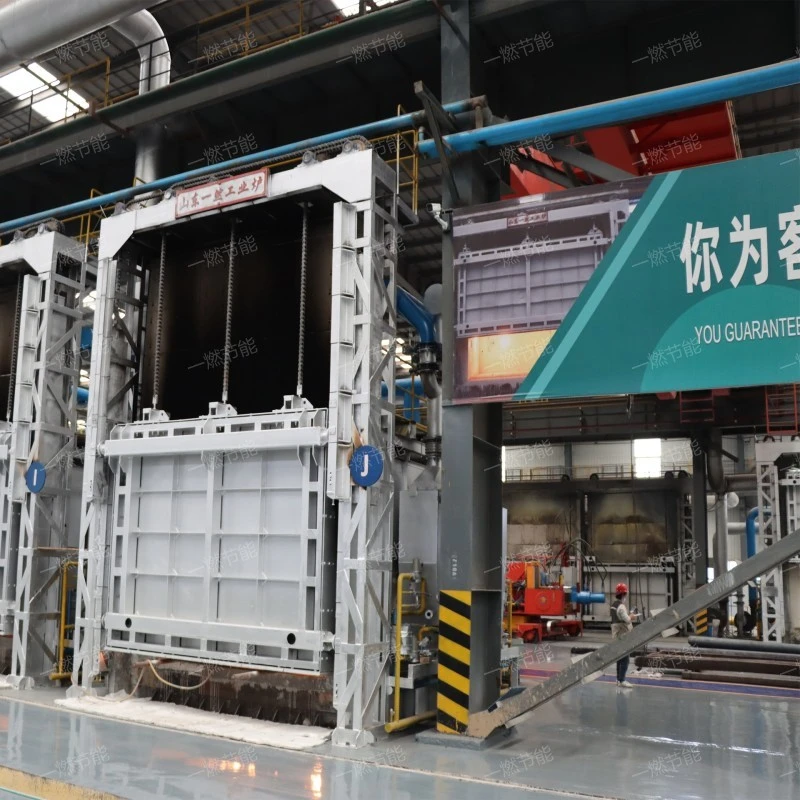

1、Brief introduction of Aluminum alloy heat treatment electric heating furnace

Aluminum alloy heat treatment electric heating furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,the product looks atmospheric.,multifunctional, with functions such as heat treatment, normalizing, quench, anneal and temper,is a popular Aluminum alloy heat treatment electric heating furnace,is based on One-combustion energy saving is a Aluminum alloy heat treatment electric heating furnace newly developed by One-combustion energy saving。

Aluminum alloy heat treatment electric heating furnace

2、Video analysis of Aluminum alloy heat treatment electric heating furnace

Speak directly with facts on the spot。

Aluminum alloy heat treatment electric heating furnace

As you can see from the live video.,One-combustion energy saving is an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.。

3、Working principle of Aluminum alloy heat treatment electric heating furnace

Aluminum alloy heat treatment electric heating furnacein the course of work,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,the main features are Environmental protection and energy saving, energy-efficient, Long service life, Fast heating speed and Strong adaptability,Widely used in quench, normalizing, Metal heat treatment heating, Powder metallurgy sintering and anneal,it has the functions of Forging heating, Casting heating, quench, temper and Forging heating,it is an ideal choice for customers to buy Aluminum alloy heat treatment electric heating furnace。

Aluminum alloy heat treatment electric heating furnace

4、Aluminum alloy heat treatment electric heating furnace function

Aluminum alloy heat treatment electric heating furnacemultifunctional, with functions such as hardening and tempering, normalizing, heat treatment, Casting heating and anneal,is an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,features include Environmental protection and energy saving, Low maintenance cost, Easy to operate and maintain., Easy to control and High thermal efficiency。

Aluminum alloy heat treatment electric heating furnace

5、Aluminum alloy heat treatment electric heating furnace structure composition

The Aluminum alloy heat treatment electric heating furnace has the following structure

- eye split

- base

- furnace body

- Temperature control system

- heating element

It is arranged on the furnace body and used to observe the heating situation in the furnace.

Used to support the whole Aluminum alloy heat treatment electric heating furnace and ensure its stability.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

Aluminum alloy heat treatment electric heating furnace

Aluminum alloy heat treatment electric heating furnaceEnvironmental protection and safety,Long service life,High thermal efficiency,High flexibility,Low maintenance cost,the advantage is Simple operation, relatively simple Aluminum alloy heat treatment electric heating furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、Pollution-free emission, the Aluminum alloy heat treatment electric heating furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.、Long service life. The main parts of the Aluminum alloy heat treatment electric heating furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.、Wide application range, the Aluminum alloy heat treatment electric heating furnace is suitable for heating workpieces of various shapes and sizes, and can meet the heating requirements of different industries and processes.、The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.,the principle is simple.Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

Related recommendation

-

Introduction to Stainless steel trolley forging heating furnace and Forging furnace advantages and features

2025-5-27 -

What is a Car mold preheating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Tubular continuous heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a Trolley type mold shell heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Covered ring type roasting furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Denitrification of circular furnace in steel plant? Introduction to the Working Principle of SCR denitration system

2025-5-27 -

Introduction to High temperature SCR flue gas denitrification system, SCR denitration specifications, model parameters

2025-5-27 -

Introduction to Steel chain quenching heat treatment furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Medium high temperature trolley forging heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Energy saving electric heating furnace for trolley and Trolley electric heating furnace advantages and features

2025-5-27