Introduction to Electric heating and heat treatment furnace and Trolley electric heating furnace advantages and features

Electric heating and heat treatment furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,features include Easy to operate and maintain., Environmental protection and safety, Long service life, energy-efficient and Easy to control,is an advanced Electric heating and heat treatment furnace developed by our company in combination with the actual situation of the industry。The following is to introduce the Electric heating and heat treatment furnace:

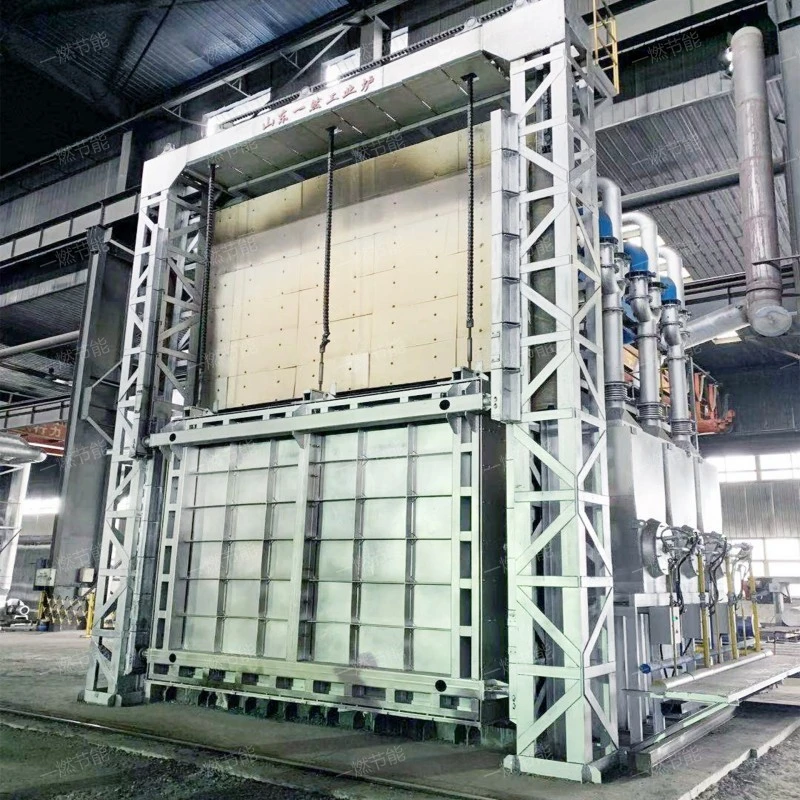

1、Brief introduction of Electric heating and heat treatment furnace

Electric heating and heat treatment furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,is based on One-combustion energy saving is a Electric heating and heat treatment furnace newly developed by One-combustion energy saving。

Electric heating and heat treatment furnace

2、Electric heating and heat treatment furnace function

Electric heating and heat treatment furnaceit has the functions of normalizing, temper, anneal, hardening and tempering and Casting heating,It has a wide range of uses, and is often used inquench,quench,hardening and tempering,normalizing,braze welding and so on,the main structure includes thermal insulation (material), heating element, furnace chamber, furnace shell, fire door and so on,productThe structural design is simple, novel and special.,it can be used in fireproofing, chemical industry, New material development, electron, Special material and other industries,the product looks beautiful.。

Electric heating and heat treatment furnace

3、Functional advantages of Electric heating and heat treatment furnace

Electric heating and heat treatment furnaces have the following advantages.

- Low maintenance cost

- High energy utilization rate

- Easy to control

- Strong customization

- easy to operate

The structure of the Electric heating and heat treatment furnace is relatively simple, and it is convenient to maintain, and the failure rate is relatively low, which helps to reduce the maintenance cost.

When the Electric heating and heat treatment furnace works, there is no smoke heat loss of the fuel furnace, so the energy utilization rate is higher, which is helpful to save energy and reduce production costs.

The furnace temperature is controlled accurately, which is convenient for automatic control.

The Electric heating and heat treatment furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.

The operation of the Electric heating and heat treatment furnace is relatively simple, and it is easy to realize automatic control, which is helpful to improve production efficiency.

Electric heating and heat treatment furnace

4、Structural advantages of Electric heating and heat treatment furnace

The Electric heating and heat treatment furnace has the following structure

- furnace body

- control system

- heating element

- Temperature control system

- thermal insulation (material)

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The control system is the command center of the Electric heating and heat treatment furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

Electric heating and heat treatment furnace

5、Electric heating and heat treatment furnace quotation

The Electric heating and heat treatment furnace price is introduced as follows:

- service

- market demand

- Cost input

- technology

- select a qualified person

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Electric heating and heat treatment furnace price and service can meet the actual needs of customers.

Some external factors, such as market conditions, economic situation, industry rules, supply-demand relationship, etc., will also lead to certain fluctuations in Electric heating and heat treatment furnace prices, so this is also the main factor affecting prices.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Electric heating and heat treatment furnace

6、One-combustion energy saving's strength

The company has many years of Electric heating and heat treatment furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Electric heating and heat treatment furnaceat runtime,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,the product looks atmospheric.,multifunctional, with functions such as quench, heat treatment, quench, anneal and Forging heating。

Related recommendation

-

Introduction to Resistance roasting furnace, how much is the price of the Trolley electric furnace?

2025-5-27 -

Introduction to SCR catalyst denitrification, SCR denitration advantages, characteristics and principles

2025-5-27 -

What is a Dual car heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

台车双门焙烧炉

2023-05-31 -

What is a Heat treatment heating resistance furnace? Introduction to the advantages and characteristics of Trolley resistance heating furnace functions

2025-5-27 -

What is a Well type quenching and annealing furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Energy saving chain heat treatment furnace and forging furnace structure principle

2025-5-27 -

天然气烧嘴

2023-03-18 -

Introduction to Industrial trolley electric heating furnace, Trolley electric heating furnace specifications, model parameters

2025-5-27 -

Introduction to Regenerative burner tube heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27