What is a Resistance heating industrial annealing furnace? Trolley electric heating furnace specifications, models, and parameters

Resistance heating industrial annealing furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,at the start of the operation,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,It is a product series that integrates hardening and tempering, Heating before metal forging, Powder metallurgy sintering, Metal heat treatment heating and braze welding,widely used in machinery, chemical industry, metallurgy, electron, glass and other fields,has been favored by more and more customers.。The following is to introduce the Resistance heating industrial annealing furnace:

1、Brief introduction of Resistance heating industrial annealing furnace

Resistance heating industrial annealing furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,it is an ideal choice for customers to buy Resistance heating industrial annealing furnace。

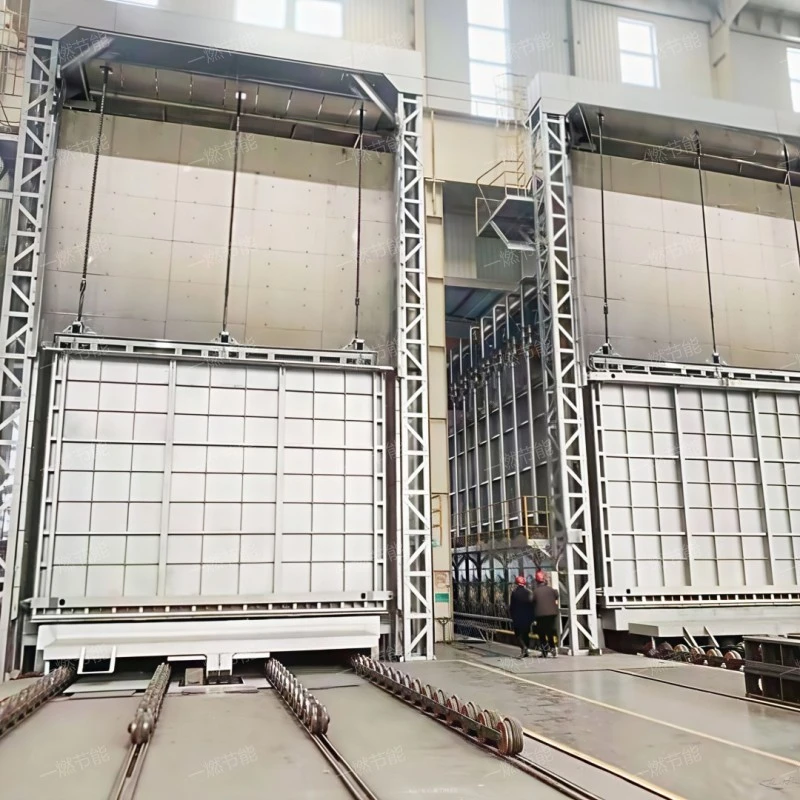

Resistance heating industrial annealing furnace

2、Advantages of Resistance heating industrial annealing furnace principle

Resistance heating industrial annealing furnaceThermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

Resistance heating industrial annealing furnace

3、Resistance heating industrial annealing furnace use

The purpose of Resistance heating industrial annealing furnace is introduced as follows:

- New material development

- powder metallurgy

- Metal melting and casting

- Metal heat treatment

- Ceramic and glass industries

Used for synthesis and heat treatment of special materials and new materials.

Used for sintering and heat treatment of powder.

Used for melting low melting point metals and alloys.

Such as quenching, normalizing, annealing, tempering, etc.

Used for baking and annealing of ceramics and glass.

Resistance heating industrial annealing furnace

4、Resistance heating industrial annealing furnace function

Resistance heating industrial annealing furnaceit has the functions of temper, normalizing, Casting heating, quench and heat treatment,it is widely used in New material development, fireproofing, pottery and porcelain, building materials and Special material。

Resistance heating industrial annealing furnace

5、Resistance heating industrial annealing furnace price consultation

The Resistance heating industrial annealing furnace price is introduced as follows:

- Product configuration difference

- type of operation

- select a qualified person

- deploy

- regional advantages

Usually, the quotation of Resistance heating industrial annealing furnace changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

If there is no middleman to earn the difference, then the Resistance heating industrial annealing furnace price will naturally decrease. One-combustion energy saving adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Resistance heating industrial annealing furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Resistance heating industrial annealing furnace is reasonable for products with the same configuration.

One-combustion energy saving the address is located at:Shandong(Province), the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

Resistance heating industrial annealing furnace

6、One-combustion energy saving's strength

The company has many years of Resistance heating industrial annealing furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Resistance heating industrial annealing furnacethe advantage is The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.、The maintenance cost is low, the Resistance heating industrial annealing furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.、The electrothermal conversion efficiency is high, and the Resistance heating industrial annealing furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.、High thermal efficiency, higher than traditional heating equipment such as flame furnace.、The safety is high, and the Resistance heating industrial annealing furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.,The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.、The energy utilization rate is high, and the Resistance heating industrial annealing furnace has no heat loss caused by the exhaust gas of the fuel furnace in the working process, so the energy utilization rate is higher, which is helpful to save energy and reduce production costs.、Simple operation, relatively simple Resistance heating industrial annealing furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、The temperature control precision is high, and the Resistance heating industrial annealing furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.、Long service life. The main parts of the Resistance heating industrial annealing furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.,Easy to control,Environmental protection and energy saving,energy-efficient,Long service life,Accurate temperature control。

Related recommendation

-

Introduction to Medium temperature trolley electric furnace, Trolley electric furnace advantages, characteristics and principles

2025-5-27 -

What is a Heat treatment equipment trolley furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Gas tube furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Forging heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Natural gas regenerative walking industrial furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Energy saving gas trolley furnace and Forging furnace working principle

2025-5-27 -

Introduction to All fiber trolley resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

What is a Quenching and tempering treatment trolley forging furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Natural gas roller bottom heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Oxidation reduction denitrification system, advantages, characteristics and principles of SCR denitration system

2025-5-27