Introduction to Industrial tube furnace and Forging furnace advantages and features

Industrial tube furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,It has a wide range of uses, including Improve production efficiency, Metal melting and casting, Metal tempering, Metal heat treatment and Metal forging heating,the product looks atmospheric.。

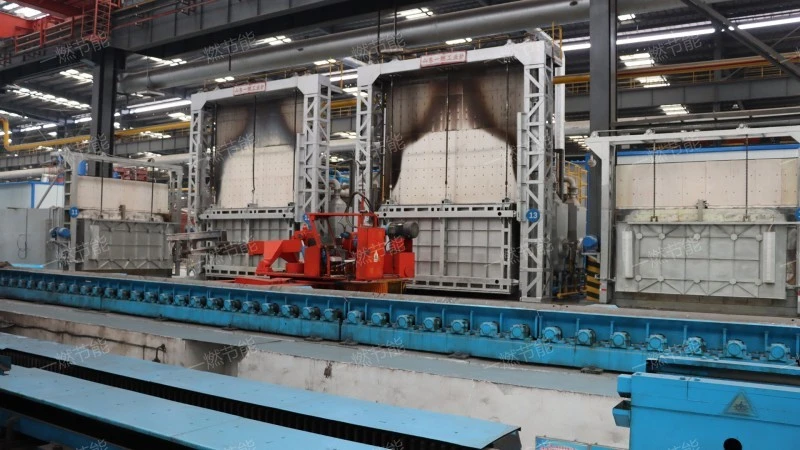

1、Brief introduction of Industrial tube furnace

Industrial tube furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Industrial tube furnace

2、Industrial tube furnace structure composition

The Industrial tube furnace structure is introduced as follows:

- ventilation system

- ventilation system

- combustor

- Radiation chamber

- furnace chamber

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The heat load of the main place for Industrial tube furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

Industrial tube furnace

3、Industrial tube furnace function

Industrial tube furnacemultifunctional, with functions such as hardening and tempering, temper, normalizing, temper and anneal,the product looks atmospheric.,it is an ideal choice for customers to buy Industrial tube furnace。

Industrial tube furnace

4、Working principle of Industrial tube furnace

Industrial tube furnacein the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it is widely used in aerospace, building materials, shipping, building materials, Machinery manufacturing and other industries。

Industrial tube furnace

5、How much is the Industrial tube furnace?

The Industrial tube furnace price is introduced as follows:

- Model type

- sales mode

- Configuration difference

- Service factor

- Manufacturer's strength

Because the specifications and models of products are different, their specifications and configurations are not the same. As we all know, the cost of products with high configuration will be higher, and vice versa, because there is a close relationship between product sales price and specifications and models.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Industrial tube furnace is low.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Industrial tube furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Industrial tube furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Industrial tube furnace price and service can meet the actual needs of customers.

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Industrial tube furnace is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Industrial tube furnace is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Industrial tube furnace

6、Company service

On the premise of ensuring high quality and low price, One-combustion energy saving can also provide customers with high-standard services, help customers choose appropriate specifications and models, and install and debug products on site for them free of charge. If customers have special requirements, our company can also train product operators in operation knowledge. Besides, if everyone's products fail at any time, our company will rush to the scene to solve them in a short time and deal with them in time.。

One-combustion energy saving

Industrial tube furnaceUsually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.,it has the functions of quench, hardening and tempering, Forging heating, heat treatment and Casting heating。

Related recommendation

-

What is a High temperature tube annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

台车式燃气炉

2023-04-22 -

台车模具预热炉

2023-05-29 -

What is a Explosion proof multi well heating furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a High temperature bright well furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Roller type roasting furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Fully enclosed gas trolley furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Multi chamber heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Regenerative gas chamber heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Natural gas chain heating furnace, how much is the price of the Forging furnace?

2025-5-27