Introduction to Industrial tube annealing furnace, introduction to heating furnace advantages and characteristics

Industrial tube annealing furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,Structure consists of convection chamber, recovery of waste heat, ventilation system, combustor, Radiation chamber and so on。The following is to introduce the Industrial tube annealing furnace:

1、Brief introduction of Industrial tube annealing furnace

Industrial tube annealing furnaceIt is a forging heating device using gas as fuel.,Widely used in Metal forging heating, Metal melting and casting, Energy conservation and environmental protection, Metal heat treatment and Metal tempering,Easy to control,Easy to maintain,Strong adaptability,energy saving and environmental protection,Stable and reliable。

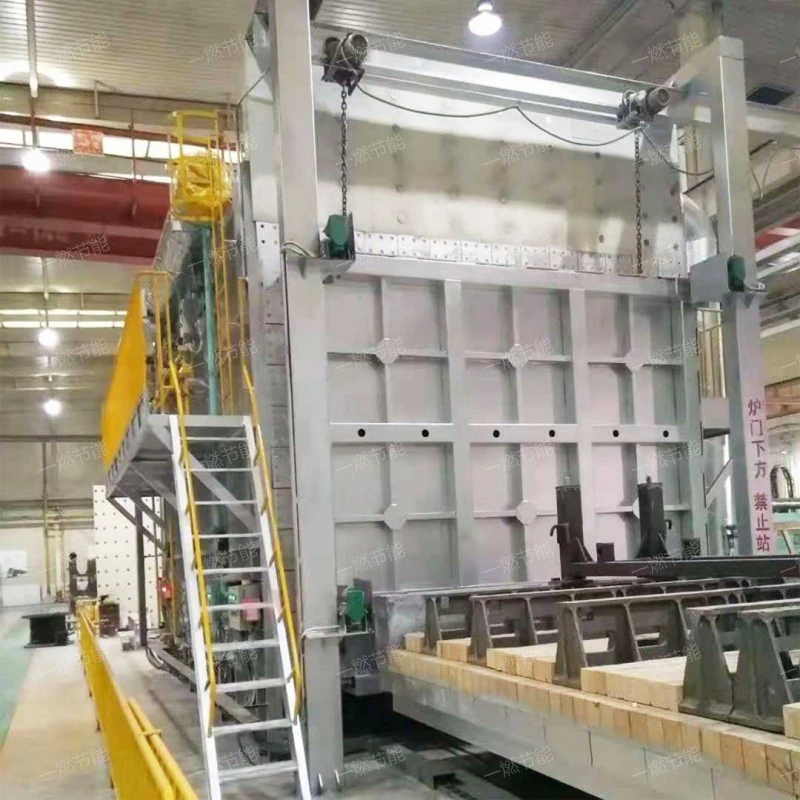

Industrial tube annealing furnace

2、Industrial tube annealing furnace characteristics

The Industrial tube annealing furnace features are as follows:

- Efficient heating

- energy saving and environmental protection

- Easy to control

- Strong adaptability

- Stable and reliable

The Industrial tube annealing furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

The combustion system and ventilation system of the Industrial tube annealing furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Industrial tube annealing furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The Industrial tube annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Industrial tube annealing furnace

3、Industrial tube annealing furnace introduction video

You can buy Industrial tube annealing furnace according to your needs and show you Industrial tube annealing furnace videos.。

Industrial tube annealing furnace

As you can see from the live video.,One-combustion energy saving it is mainly composed of ventilation system, furnace chamber, ventilation system, recovery of waste heat and Radiation chamber,productThe structural design is more advanced and reasonable.。

4、Industrial tube annealing furnace use

The purpose of Industrial tube annealing furnace is introduced as follows:

- Metal forging heating

- Metal forging heating

- Energy conservation and environmental protection

- Metal melting and casting

- Metal heat treatment

The Industrial tube annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Industrial tube annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Industrial tube annealing furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Although it is mainly used for forging heating, some types of Industrial tube annealing furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Industrial tube annealing furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Industrial tube annealing furnace

5、Industrial tube annealing furnace advantage

The advantages of Industrial tube annealing furnace are as follows:

- Improve product quality

- Multiple fuel options

- easy to operate

- Rapid temperature rise

- Extend the service life of equipment

Because the Industrial tube annealing furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

Although the Industrial tube annealing furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The operation interface of the Industrial tube annealing furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Industrial tube annealing furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The Industrial tube annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Industrial tube annealing furnace

6、Industrial tube annealing furnace price advantage

The Industrial tube annealing furnace price is introduced as follows:

- technology

- raw material

- Cost input

- cost of production

- Company size

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Cost is a direct and fundamental factor that affects the price of Industrial tube annealing furnace. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in Industrial tube annealing furnace price, low in cost and low in price.

The products manufactured by manufacturers of different scales are also different. Large-scale manufacturers have advanced production technology, the quality of products manufactured is reliable, and large-scale manufacturers have perfect after-sales service, which can provide greater protection for customers and the products manufactured are more cost-effective. Therefore, customers should try to choose large manufacturers to purchase.

Industrial tube annealing furnace

Industrial tube annealing furnacethe product looks beautiful.,features include Easy to control, Easy to maintain, energy-efficient, Strong adaptability and Stable and reliable,It is mostly used in Improve production efficiency, Energy conservation and environmental protection, Improve production efficiency, Metal heat treatment, Metal forging heating, Metal melting and casting and so on。

Related recommendation

-

Introduction to Trolley high-temperature heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Hot rolling roll heat treatment industrial furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Continuous bright annealing heat treatment furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Regenerative burner chain heat treatment furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Gas storage roller furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Steel plant annealing furnace flue gas denitrification system and SCR denitration system advantages and features

2025-5-27 -

What is a Gas storage gas trolley furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

What is a Automatic loading and unloading resistance heating furnace? Introduction to the advantages and characteristics of the Trolley resistance furnace

2025-5-27 -

Introduction to Full fiber heat treatment heating furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Tempering heat treatment electric heating furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

2025-5-27