What is a Chain iron core annealing furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

Chain iron core annealing furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,is a popular Chain iron core annealing furnace。

1、Brief introduction of Chain iron core annealing furnace

Chain iron core annealing furnaceIt is a forging heating device using gas as fuel.,in the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,the main structure includes furnace chamber, combustor, Radiation chamber, convection chamber, ventilation system and so on。

Chain iron core annealing furnace

2、Chain iron core annealing furnace explanation video

You can buy Chain iron core annealing furnace according to your needs and show you Chain iron core annealing furnace videos.。

Chain iron core annealing furnace

As you can see from the live video.,One-combustion energy saving It is a product series that integrates Metal tempering, Metal heat treatment, Energy conservation and environmental protection, Improve production efficiency and Metal forging heating。

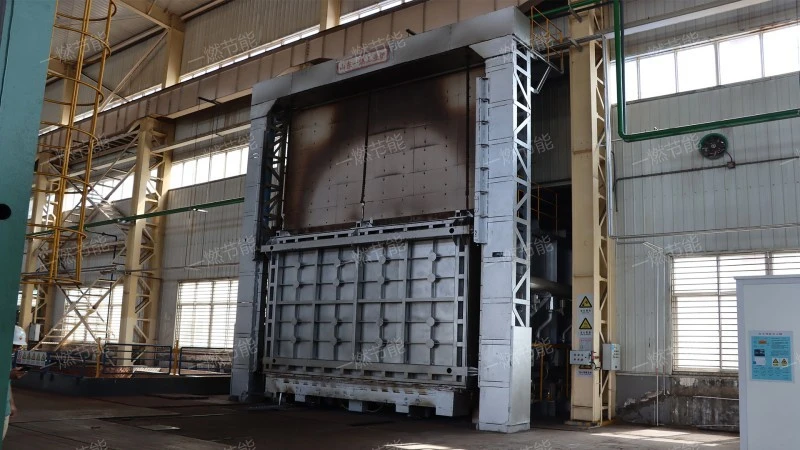

3、Chain iron core annealing furnace field real shot

Overview of high-definition pictures,the product looks atmospheric., different specifications and models。

Chain iron core annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Advantages of Chain iron core annealing furnace principle

Chain iron core annealing furnaceat work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,It has a wide range of uses, and is often used inMetal melting and casting,Metal tempering,Metal melting and casting,Energy conservation and environmental protection,Improve production efficiency and so on,the product looks beautiful.,multifunctional, with functions such as Forging heating, Casting heating, heat treatment, quench and Forging heating,is based on One-combustion energy saving is a kind of Chain iron core annealing furnace manufactured by One-combustion energy saving。

Chain iron core annealing furnace

5、Introduction of advantages of Chain iron core annealing furnace

Chain iron core annealing furnaces have the following advantages.

- Extend the service life of equipment

- Uniform heating

- Multiple fuel options

- Extend the service life of equipment

- Uniform heating

The Chain iron core annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Chain iron core annealing furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Although the Chain iron core annealing furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Chain iron core annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Chain iron core annealing furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Chain iron core annealing furnace

6、Chain iron core annealing furnace function

Chain iron core annealing furnacemultifunctional, with functions such as hardening and tempering, temper, quench, Forging heating and hardening and tempering,it has been widely used in war industry, Machinery manufacturing, shipping, Household necessities, metallurgy and other industries,The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.,customizable。

Chain iron core annealing furnace

Chain iron core annealing furnaceit has the functions of quench, temper, heat treatment, anneal and normalizing,widely used inpharmacy,chemical industry,surface treatment,heat treatment,electron and other industries。

Related recommendation

-

Introduction to Mold shell heating furnace and forging furnace working principle

2025-5-27 -

Introduction to Forging natural gas trolley furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

模具台车锻造炉

2023-09-15 -

What is a Double trolley aluminum alloy furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Casting forging furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Steel plant denitrification? Introduction to the principle of SCR denitration system structure

2025-5-27 -

What is a Energy saving and environmentally friendly roller bottom heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Fully automatic trolley forging heating furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to SCR catalytic denitrification, introduction to SCR denitration function advantages and characteristics

2025-5-27 -

What is a Regenerative burner trolley forging heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27