What is a Pit type heating furnace? heating furnace specifications, models, and parameters

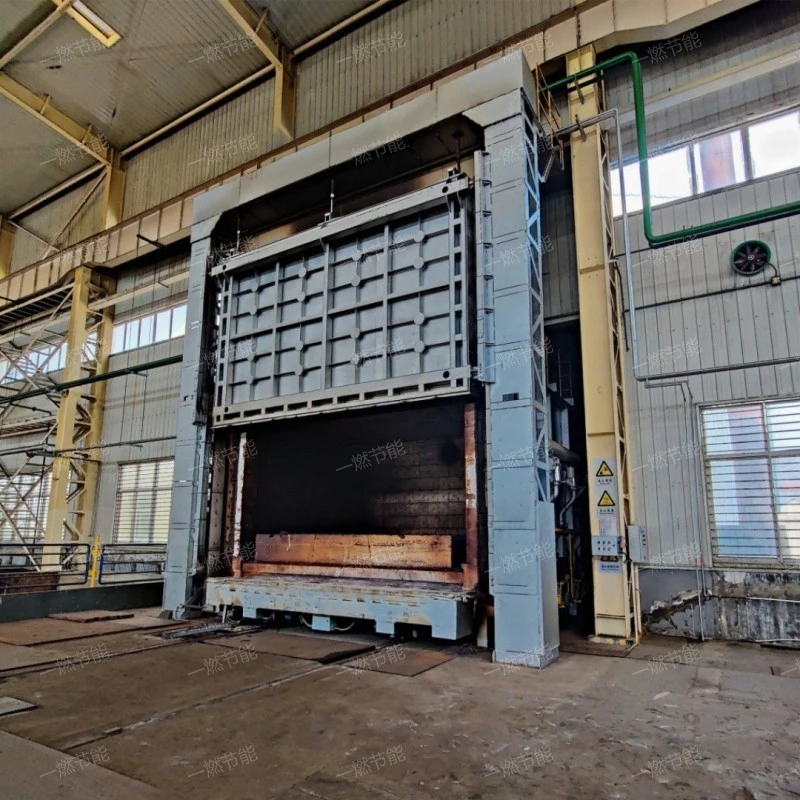

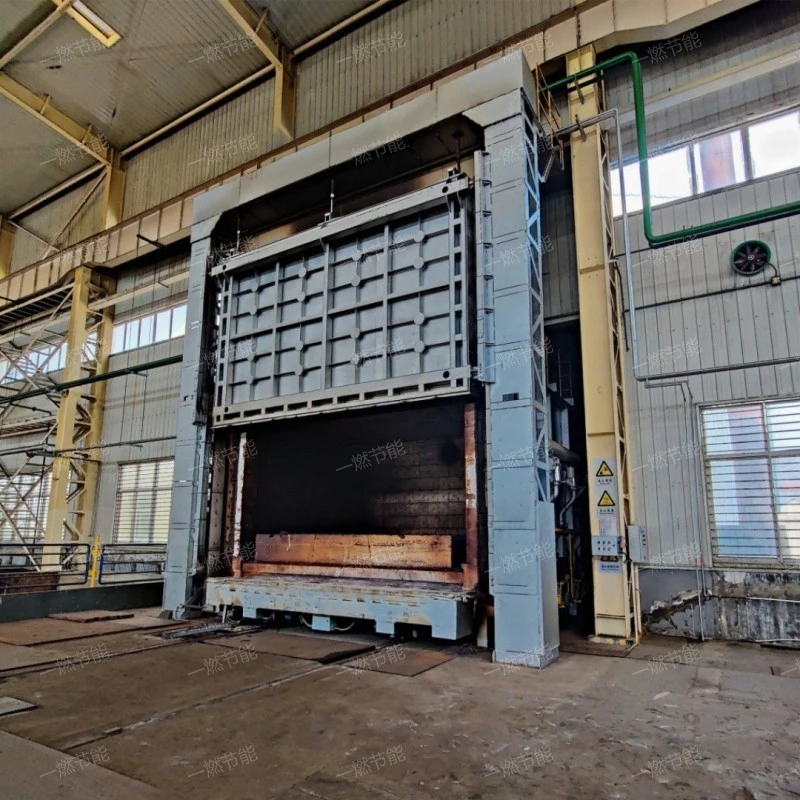

Pit type heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it has the functions of hardening and tempering, quench, hardening and tempering, heat treatment and anneal,is a kind of high quality and low price Pit type heating furnace,the product looks atmospheric.,was developed and designed by One-combustion energy saving。The following is to introduce the Pit type heating furnace:

1、Brief introduction of Pit type heating furnace

Pit type heating furnaceIt is a forging heating device using gas as fuel.,at the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,the main structure includes combustor, convection chamber, ventilation system, Radiation chamber, ventilation system and so on,This Pit type heating furnaceThe overall structural design is simple, diverse and beautiful.。

Pit type heating furnace

2、Pit type heating furnace function

Pit type heating furnaceit has the functions of normalizing, temper, Forging heating, Casting heating and quench,the advantage is Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.,the principle is simple.The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,it is widely used in Household necessities, petroleum, surface treatment, Machinery manufacturing and heat treatment,It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

Pit type heating furnace

3、Structural advantages of Pit type heating furnace

The Pit type heating furnace has the following structure

- ventilation system

- combustor

- Waste heat recovery system

- furnace chamber

- combustor

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Pit type heating furnace

4、Pit type heating furnace application

Pit type heating furnaces have the following purposes.

- Improve production efficiency

- Metal forging heating

- Metal melting and casting

- Metal heat treatment

- Metal melting and casting

The Pit type heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Pit type heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Although it is mainly used for forging heating, some types of Pit type heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Pit type heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Although it is mainly used for forging heating, some types of Pit type heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

Pit type heating furnace

5、Pit type heating furnace price concessions

The Pit type heating furnace price is introduced as follows:

- product function

- product costs

- Manufacturer's strength

- brand

- sales mode

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Pit type heating furnace just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

There are many manufacturers of products in Jinan, Shandong province, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Pit type heating furnace is naturally different.

Different brands of products in the same series have more or less differences in product prices, and different brands of Pit type heating furnace have more or less differences in price.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Pit type heating furnace is low.

Pit type heating furnace

6、One-combustion energy saving after-sales service

Users should not only consider the quality, performance and price factors when buying Pit type heating furnace, but also consider the after-sales service of manufacturers. Good after-sales service can reduce many unnecessary troubles for customers. One-combustion energy saving manufacturers always adhere to the service attitude of "customer is God", implement high-standard and high-quality after-sales service attitude, conduct regular customer satisfaction surveys, and strictly supervise the quality of after-sales service, so as to relieve customers' purchase worries and make buyers completely worry-free.。

One-combustion energy saving

Pit type heating furnaceat runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,is a Pit type heating furnace,It has the functions of Improve production efficiency, Metal forging heating, Metal tempering, Energy conservation and environmental protection and Metal heat treatment。

Related recommendation

-

What is a Cover ring type mold shell roasting furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Fully automatic trolley furnace and Forging furnace working principle

2025-5-27 -

What is a Fully automatic heat treatment heating furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Stick style spheroidization annealing furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Carburizing furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Dual car rapid quenching furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Automatic temperature regulating tube annealing furnace? How much is the price of the Forging furnace?

2025-5-27 -

What is a Heat treatment well furnace? How much is the price of the heating furnace?

2025-5-27 -

What is a Chain belt industrial furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to All carbon fiber high-temperature trolley forging furnace, introduction to forging furnace advantages and characteristics

2025-5-27