Introduction to Full fiber well furnace, introduction to forging furnace advantages and characteristics

Full fiber well furnaceIt is a forging heating device using gas as fuel.,Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.,it is widely used in machinery, shipping, metallurgy, aerospace, surface treatment and other industries。The following is to introduce the Full fiber well furnace:

1、Brief introduction of Full fiber well furnace

Full fiber well furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the main structure includes furnace chamber, convection chamber, recovery of waste heat, combustor and ventilation system,Easy to control,Easy to maintain,Stable and reliable,energy saving and environmental protection,energy-efficient,has been favored by more and more customers.。

Full fiber well furnace

2、Full fiber well furnace function

Full fiber well furnaceit has the functions of quench, hardening and tempering, Forging heating, normalizing and heat treatment,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,The price is more affordable。

Full fiber well furnace

3、Full fiber well furnace characteristics

The Full fiber well furnace features are as follows:

- Efficient heating

- Stable and reliable

- Strong adaptability

- Easy to control

- Easy to control

The Full fiber well furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

The Full fiber well furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Full fiber well furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The combustion system and ventilation system of the Full fiber well furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Full fiber well furnace

4、Full fiber well furnace structure

The Full fiber well furnace structure is introduced as follows:

- combustor

- furnace chamber

- Radiation chamber

- convection chamber

- ventilation system

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

A space for holding metallic materials for heating.

The heat load of the main place for Full fiber well furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Full fiber well furnace

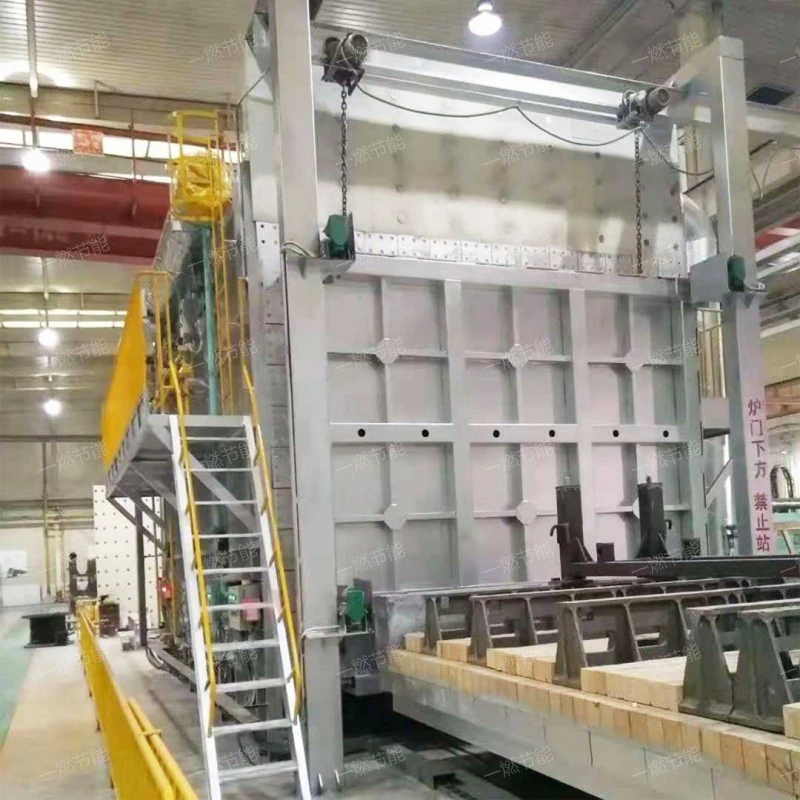

5、Physical picture of Full fiber well furnace

One-combustion energy saving Full fiber well furnacethe product looks beautiful., the picture is taken.。

Full fiber well furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、Full fiber well furnace price concessions

The Full fiber well furnace price is introduced as follows:

- product function

- Company size

- product quality

- Cost input

- geographical position

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Our company's expected profit value of Full fiber well furnace is relatively low, and adopts the sales policy of small profits but quick turnover, so the price positioning of Full fiber well furnace is relatively low.

The selling price of excellent quality products is also high, so users should also consider the quality and price of products comprehensively when purchasing products, so as to buy products with high cost performance.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

Full fiber well furnace

Full fiber well furnacethe product looks atmospheric.,multifunctional, with functions such as anneal, Forging heating, hardening and tempering, normalizing and anneal,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

Introduction to Low temperature SCR method for denitrification, introduction to SCR flue gas denitrification advantages and characteristics

2025-5-27 -

What is a Automatic entry and exit forging heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Bright heat treatment heating furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Dual car high-temperature calcination furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Industrial tubular heating furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Spheroidization annealing industrial furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Walking beam industrial furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Aluminum alloy heat treatment electric heating furnace, how much is the price of the Trolley electric furnace?

2025-5-27 -

What is a Segmented natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Square steel heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27