Introduction to Rotary resistance heating furnace, introduction to Trolley resistance heating furnace advantages and characteristics

Rotary resistance heating furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,is a kind of Rotary resistance heating furnace manufactured by One-combustion energy saving。

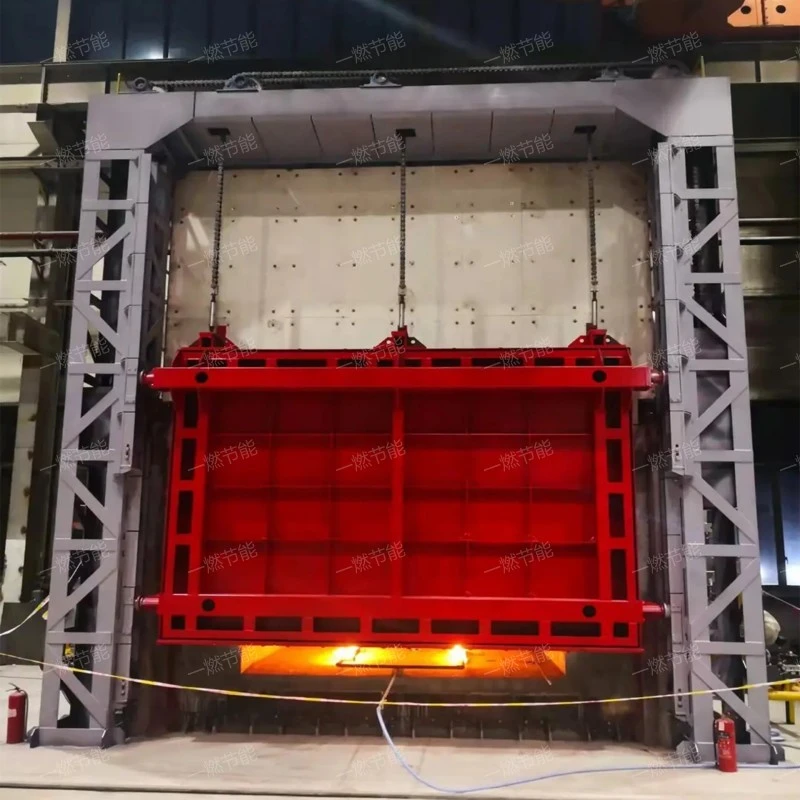

1、Brief introduction of Rotary resistance heating furnace

Rotary resistance heating furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,High flexibility,Electrothermal conversion efficiency,Strong adaptability,High thermal efficiency,Accurate temperature control,the principle is simple.Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,It can be used for anneal, hardening and tempering, braze welding, Powder metallurgy sintering, Metal heat treatment heating, quench and so on,is based on One-combustion energy saving is carefully developed by One-combustion energy saving combined with advanced technology。

Rotary resistance heating furnace

2、Functional advantages of Rotary resistance heating furnace

Rotary resistance heating furnaces have the following advantages.

- rapid heating

- Good temperature uniformity

- High security

- easy to operate

- Wide application range

The Rotary resistance heating furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, direct heating, current directly through the material, heating faster.

The temperature distribution in the Rotary resistance heating furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.

The Rotary resistance heating furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.

The operation of the Rotary resistance heating furnace is relatively simple, and it is easy to realize automatic control, which is helpful to improve production efficiency.

Rotary resistance heating furnaces are suitable for heating workpieces of various shapes and sizes, and can meet the heating needs of different industries and processes.

Rotary resistance heating furnace

3、Rotary resistance heating furnace application

Rotary resistance heating furnaces have the following purposes.

- Metal heat treatment

- New material development

- powder metallurgy

- Ceramic and glass industries

- Metal melting and casting

Such as quenching, normalizing, annealing, tempering, etc.

Used for synthesis and heat treatment of special materials and new materials.

Used for sintering and heat treatment of powder.

Used for baking and annealing of ceramics and glass.

Used for melting low melting point metals and alloys.

Rotary resistance heating furnace

4、Working principle of Rotary resistance heating furnace

Rotary resistance heating furnaceat runtime,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,the product looks beautiful.,it is an ideal choice for customers to buy Rotary resistance heating furnace。

Rotary resistance heating furnace

5、Rotary resistance heating furnace function

Rotary resistance heating furnacemultifunctional, with functions such as heat treatment, anneal, quench, Forging heating and temper,be of high quality,The price is low and affordable。

Rotary resistance heating furnace

6、Rotary resistance heating furnace price consultation

The Rotary resistance heating furnace price is introduced as follows:

- Less intermediate links

- Brand strength

- product function

- Product technology

- Parameter size

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

At present, there are various brands of Rotary resistance heating furnace in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Rotary resistance heating furnace are different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Products generally have a variety of specifications and models to meet the multiple needs of manufacturing. The same is true for Rotary resistance heating furnace, which have different models and different performances. Therefore, these are all factors that affect the price change of Rotary resistance heating furnace.

Rotary resistance heating furnace

Rotary resistance heating furnaceit has the functions of normalizing, Casting heating, hardening and tempering, heat treatment and hardening and tempering,It has the functions of normalizing, anneal, normalizing, Melting of low melting point metal and hardening and tempering。

Related recommendation

-

Introduction to Natural gas thermal storage tubular roaster, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Roller shaft quenching heat treatment furnace and heating furnace advantages and features

2025-5-27 -

What is a Trolley type mold shell heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

回火燃气台车炉

2023-08-31 -

Introduction to Roller type isothermal quenching furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Continuous roller bottom heating furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Isothermal well type heat treatment furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Industrial well type heat treatment furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Dual car carbonization furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Dual car preheating furnace, heating furnace specifications, model parameters

2025-5-27