Brief introduction and advantages of Four stage continuous heating furnace

Four stage continuous heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,The overall structural design is relatively simple,it is mainly composed of furnace chamber, Radiation chamber, combustor, recovery of waste heat and furnace chamber,It has a wide range of uses, and is often used inEnergy conservation and environmental protection,Metal tempering,Metal melting and casting,Improve production efficiency,Metal forging heating and so on,Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.,was developed and designed by One-combustion energy saving。The following is to introduce the Four stage continuous heating furnace:

1、Brief introduction of Four stage continuous heating furnace

Four stage continuous heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it is widely used in war industry, heat treatment, chemical industry, machinery, aerospace and other industries。

Four stage continuous heating furnace

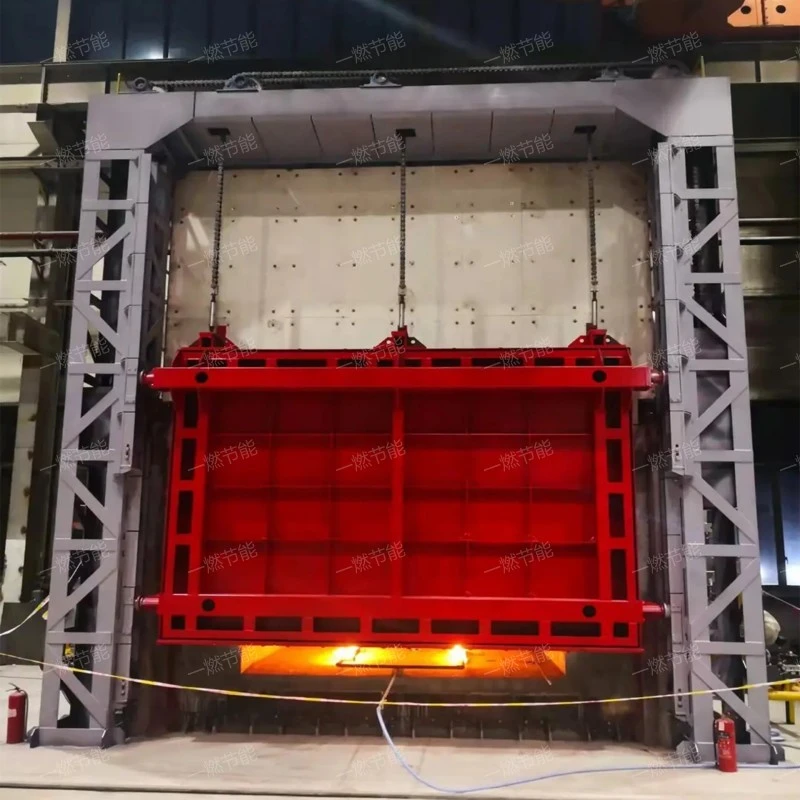

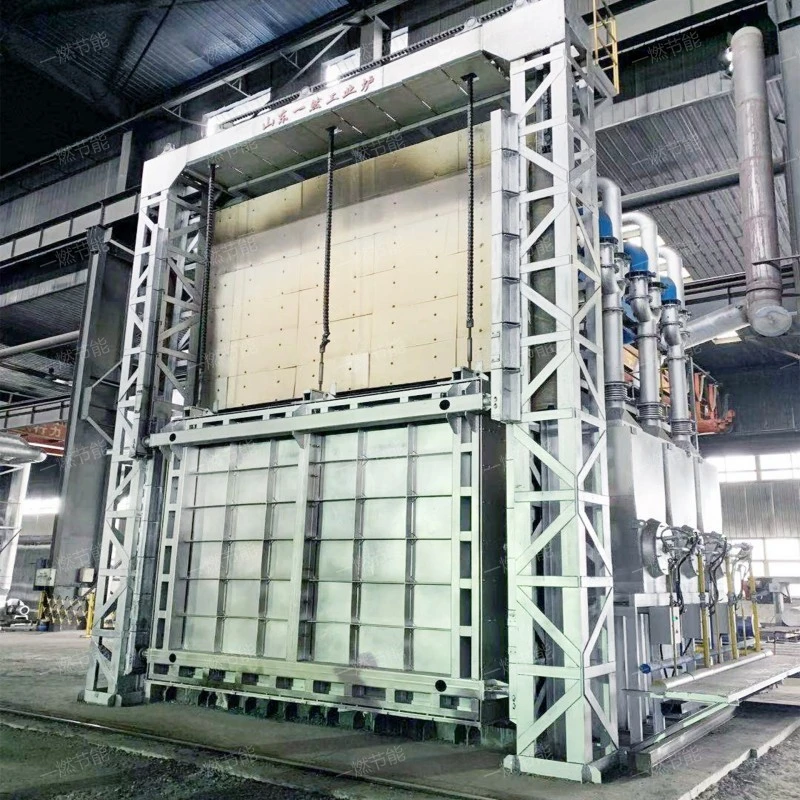

2、Four stage continuous heating furnace real shot picture

A high-definition picture list of Four stage continuous heating furnace is available for our customers to visit. The physical visit can be made to the factory. The address of the visit is Jinan, and the time can be reserved in advance. The manufacturer has a special person to receive it.。

Four stage continuous heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Introduction of Four stage continuous heating furnace characteristics

Four stage continuous heating furnace has the following characteristics

- Strong adaptability

- Easy to maintain

- Stable and reliable

- Stable and reliable

- Strong adaptability

The Four stage continuous heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The structural design of the Four stage continuous heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Four stage continuous heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Four stage continuous heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Four stage continuous heating furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

Four stage continuous heating furnace

4、Structural advantages of Four stage continuous heating furnace

The Four stage continuous heating furnace has the following structure

- Radiation chamber

- ventilation system

- Waste heat recovery system

- Radiation chamber

- ventilation system

The heat load of the main place for Four stage continuous heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The heat load of the main place for Four stage continuous heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Four stage continuous heating furnace

5、Four stage continuous heating furnace video detail

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Four stage continuous heating furnace production process and production site, and gain favorable comments and recognition from customers.。

Four stage continuous heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it has the functions of Casting heating, normalizing, anneal, quench and heat treatment。

6、Four stage continuous heating furnace price concessions

The Four stage continuous heating furnace price is introduced as follows:

- model

- technology content

- raw material

- market demand

- service

Because there are many specifications and models of Four stage continuous heating furnace, the quotations of Four stage continuous heating furnace with different specifications and models are different.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

In order to build their own brands, some manufacturers deliberately reduce the price of Four stage continuous heating furnace. The price of competitors will affect the pricing of equipment more or less, and the price may be lower.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Four stage continuous heating furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Four stage continuous heating furnace price can meet the purchasing needs of customers.

Four stage continuous heating furnace

Four stage continuous heating furnaceIt has a wide range of uses, including Metal forging heating, Energy conservation and environmental protection, Metal heat treatment, Metal tempering and Metal melting and casting,the product looks atmospheric.,at the start of the operation,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.。

Related recommendation

-

Introduction to Automatic temperature control trolley heating furnace and forging furnace working principle

2025-5-27 -

Introduction to Rail type trolley forging heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Bearing heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Split type quenching heating furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Industrial furnace multi chamber type? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Rotary forging furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Natural gas tube quenching furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Regenerative burner tube heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Regenerative burner tube annealing furnace and forging furnace working principle

2025-5-27 -

台车钢管退火炉

2023-05-16