What is a Continuous roll roasting furnace?

Continuous roll roasting furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it has the functions of quench, normalizing, anneal, Casting heating and normalizing,The price is more affordable。The following is to introduce the Continuous roll roasting furnace:

1、Brief introduction of Continuous roll roasting furnace

Continuous roll roasting furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.。

Continuous roll roasting furnace

2、Continuous roll roasting furnace use

The purpose of Continuous roll roasting furnace is introduced as follows:

- Energy conservation and environmental protection

- Metal forging heating

- Metal tempering

- Energy conservation and environmental protection

- Metal forging heating

The Continuous roll roasting furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Continuous roll roasting furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

By properly heating and cooling the metal material, the Continuous roll roasting furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Continuous roll roasting furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Continuous roll roasting furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Continuous roll roasting furnace

3、Continuous roll roasting furnace advantage

The advantages of Continuous roll roasting furnace are as follows:

- Wide application range

- Multiple fuel options

- Improve product quality

- clean energy

- Intelligent control

The Continuous roll roasting furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Although the Continuous roll roasting furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

Because the Continuous roll roasting furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

The Continuous roll roasting furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Continuous roll roasting furnace

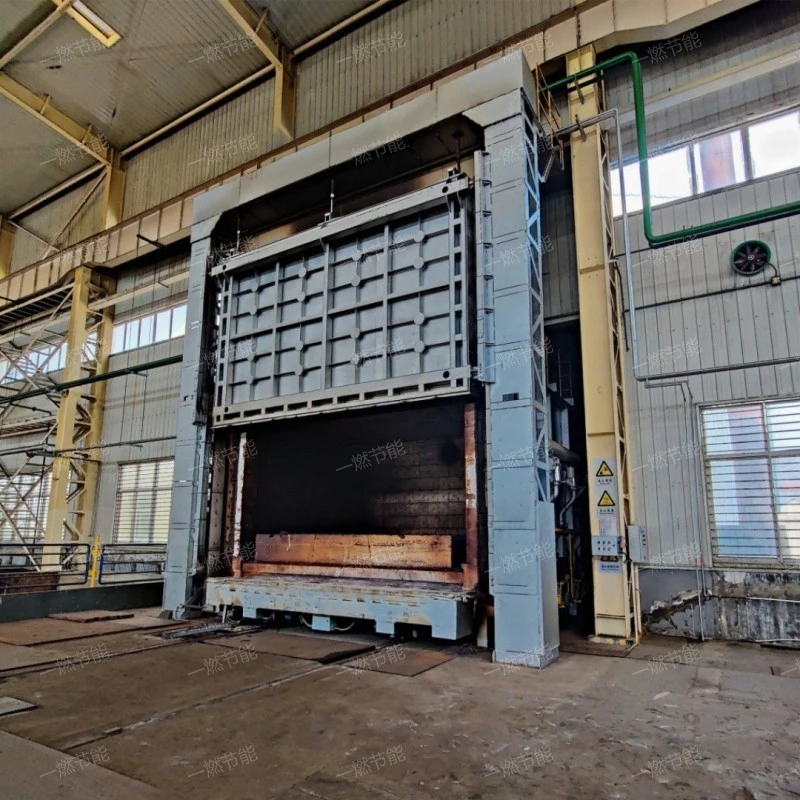

4、Continuous roll roasting furnace working site

Speak directly with facts on the spot。

Continuous roll roasting furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the principle is simple.Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

5、Continuous roll roasting furnace price advantage

The Continuous roll roasting furnace price is introduced as follows:

- product function

- technology content

- product costs

- service

- regional advantages

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Continuous roll roasting furnace just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Continuous roll roasting furnace price and service can meet the actual needs of customers.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Continuous roll roasting furnace.

Continuous roll roasting furnace

6、One-combustion energy saving service

One-combustion energy saving Continuous roll roasting furnace has been widely loved by users since it went on the market. Factory services include three aspects: pre-sale, in-sale and after-sale. Each stage is closely connected with each other, sincerely serving each customer, focusing on the production needs of customers, providing customers with product knowledge training, regularly repairing products for customers, etc., which has been appreciated by our customers.。

One-combustion energy saving

Continuous roll roasting furnacethe main structure includes combustor, convection chamber, Radiation chamber, recovery of waste heat, ventilation system and so on,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.。

Related recommendation

-

Introduction to Electric heating annealing furnace, how much is the price of the Trolley electric furnace?

2025-5-27 -

What is a Automatic temperature control chain with annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Trolley circulating furnace and forging furnace working principle

2025-5-27 -

Introduction to Gas trolley forging heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Heat treatment heating electric furnace? Trolley electric heating furnace specifications, models, and parameters

2025-5-27 -

What is a High temperature bright annealing heat treatment furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Industrial experimental resistance heating furnace? Introduction to the advantages and characteristics of Trolley resistance heating furnace functions

2025-5-27 -

Introduction to Rotary heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Tempering furnace chamber type, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Double chamber quenching industrial furnace and Forging furnace advantages and features

2025-5-27