Introduction to Mobile electric heating furnace, Trolley electric furnace advantages, characteristics and principles

Mobile electric heating furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,The structure is novel, special, advanced, reasonable and scientific.,it is mainly composed of furnace chamber, furnace shell, Temperature control system, thermal insulation (material) and fire door。The following is to introduce the Mobile electric heating furnace:

1、Brief introduction of Mobile electric heating furnace

Mobile electric heating furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,It has a wide range of uses, including Melting of low melting point metal, quench, braze welding, Powder metallurgy sintering and Roasting and annealing of glass ceramics,it is widely used in glass, pottery and porcelain, electron, chemical industry, metallurgy and other industries,has been favored by more and more customers.。

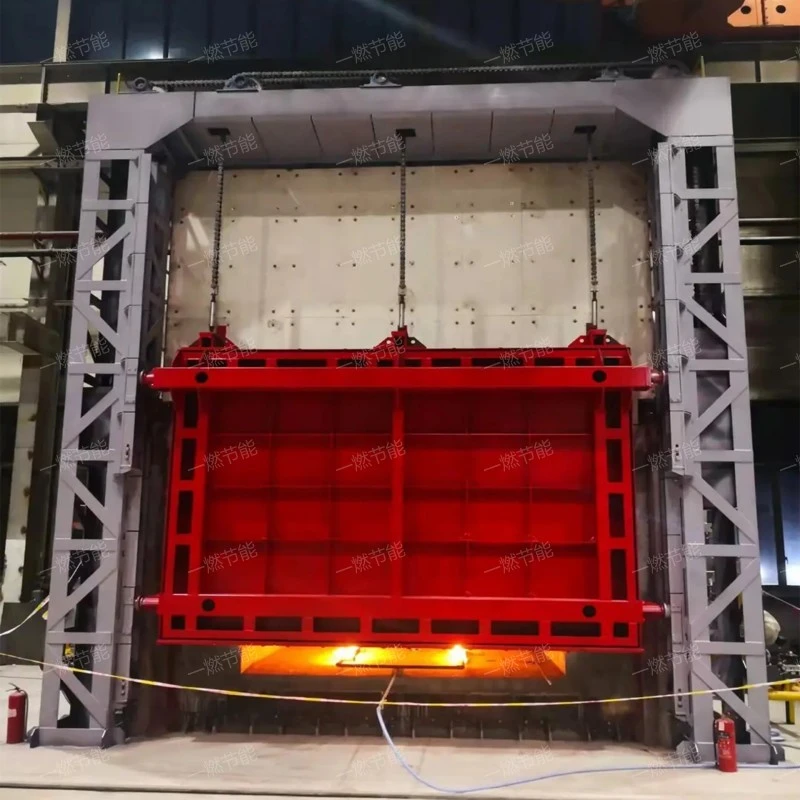

Mobile electric heating furnace

2、Mobile electric heating furnace function

Mobile electric heating furnacemultifunctional, with functions such as hardening and tempering, Forging heating, heat treatment, temper and Casting heating,the main structure includes heating element, Temperature control system, thermal insulation (material), furnace chamber, furnace shell and so on,widely used in electron, Special material, building materials, fireproofing, glass and other fields。

Mobile electric heating furnace

3、Mobile electric heating furnace application

The purpose of Mobile electric heating furnace is introduced as follows:

- Metal melting and casting

- Ceramic and glass industries

- Metal heat treatment

- powder metallurgy

- New material development

Used for melting low melting point metals and alloys.

Used for baking and annealing of ceramics and glass.

Such as quenching, normalizing, annealing, tempering, etc.

Used for sintering and heat treatment of powder.

Used for synthesis and heat treatment of special materials and new materials.

Mobile electric heating furnace

4、Mobile electric heating furnace principle

Mobile electric heating furnaceThermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,is carefully developed by One-combustion energy saving combined with advanced technology。

Mobile electric heating furnace

5、Mobile electric heating furnace structure composition

The Mobile electric heating furnace structure is introduced as follows:

- fire door

- control system

- furnace shell

- furnace body

- thermal insulation (material)

The furnace Mobile electric heating furnace is the passage for operators to enter and leave the furnace, and it also plays a certain sealing role. It can effectively prevent the heat in the furnace from leaking out and the cold air from outside from entering, and ensure the stability of the temperature in the furnace.

The control system is the command center of the Mobile electric heating furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

The furnace shell is usually made of steel plate for protection.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

Mobile electric heating furnace

Mobile electric heating furnaceit has the functions of anneal, quench, quench, heat treatment and temper,It has the functions of Metal heat treatment heating, anneal, normalizing, Roasting and annealing of glass ceramics and Powder metallurgy sintering,the main features are Low maintenance cost, Electrothermal conversion efficiency, Fast heating speed, Environmental protection and safety and energy-efficient。

Related recommendation

-

What is a Tempering heat treatment resistance heating furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

环形台车炉

2023-08-20 -

What is a Regenerative box type heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

台车式热处理炉

2023-06-12 -

What is a Automatic temperature regulating box type heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Progressive heating furnace for steel mills, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Gas roller bottom heating furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

Introduction to All fiber trolley resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

What is a Automatic temperature control trolley forging heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Square steel heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27