What is a Tempering heat treatment resistance heating furnace? Introduction to the Working Principle of Trolley resistance furnace

Tempering heat treatment resistance heating furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,the principle is simple.Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,widely used in metallurgy, New material development, electron, chemical industry, building materials and other fields,Widely used in hardening and tempering, Powder metallurgy sintering, anneal, quench and quench,at the start of the operation,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.。

1、Brief introduction of Tempering heat treatment resistance heating furnace

Tempering heat treatment resistance heating furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,is a Tempering heat treatment resistance heating furnace,structure mainly includes: heating element, furnace shell, Temperature control system, thermal insulation (material), fire door and so on,has been favored by more and more customers.。

Tempering heat treatment resistance heating furnace

2、Advantages of Tempering heat treatment resistance heating furnace principle

Tempering heat treatment resistance heating furnaceat work,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,The overall structural design is relatively simple,it is mainly composed of heating element, furnace chamber, furnace shell, fire door and Temperature control system。

Tempering heat treatment resistance heating furnace

3、Tempering heat treatment resistance heating furnace function

Tempering heat treatment resistance heating furnaceit has the functions of heat treatment, anneal, heat treatment, Forging heating and quench,Widely used inPowder metallurgy sintering,normalizing,Melting of low melting point metal,Roasting and annealing of glass ceramics,Metal heat treatment heating and so on,it is widely used in New material development, building materials, metallurgy, glass and Special material,is carefully developed by One-combustion energy saving combined with advanced technology。

Tempering heat treatment resistance heating furnace

4、Tempering heat treatment resistance heating furnace structure composition

The Tempering heat treatment resistance heating furnace structure is introduced as follows:

- base

- control system

- furnace shell

- furnace body

- Temperature control system

Used to support the whole Tempering heat treatment resistance heating furnace and ensure its stability.

The control system is the command center of the Tempering heat treatment resistance heating furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

The furnace shell is usually made of steel plate for protection.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

Tempering heat treatment resistance heating furnace

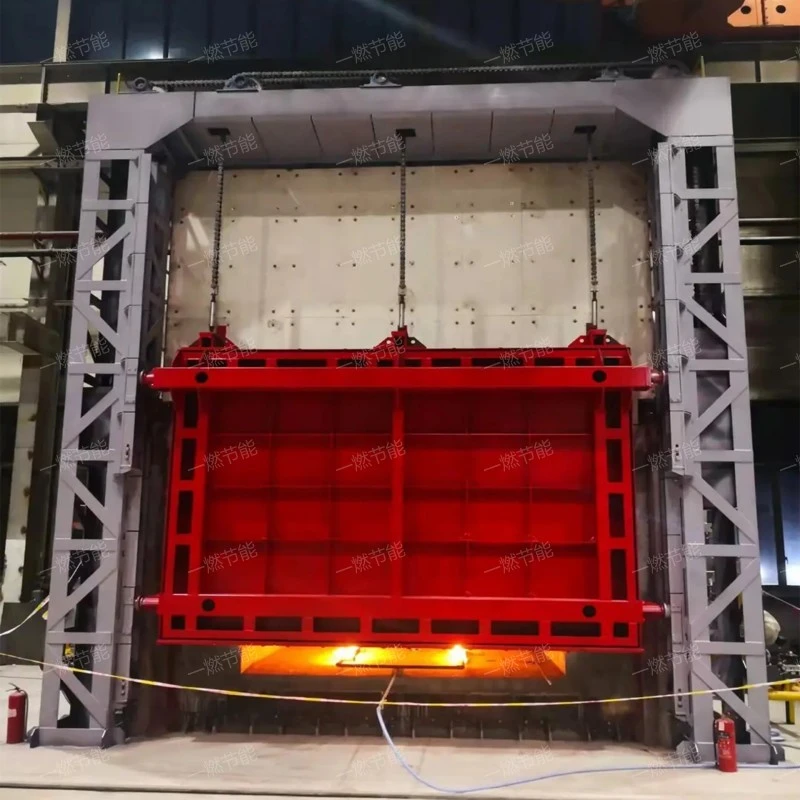

5、Tempering heat treatment resistance heating furnace introduction video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Tempering heat treatment resistance heating furnace

As you can see from the live video.,One-combustion energy saving it is widely used in chemical industry, electron, fireproofing, machinery, pottery and porcelain and other industries。

6、Tempering heat treatment resistance heating furnace price advantage

The Tempering heat treatment resistance heating furnace price is introduced as follows:

- brand

- market supply and demand

- marketing channel

- market competition

- Manufacturer scale

Different brands of products in the same series have more or less differences in product prices, and different brands of Tempering heat treatment resistance heating furnace have more or less differences in price.

The amount of customers' demand for Tempering heat treatment resistance heating furnace in the market also has a great influence on the price. When there are many customers purchasing this product in the market and the supply quantity of manufacturers is small, the Tempering heat treatment resistance heating furnace price will be very high. On the contrary, when fewer customers purchase this product, there will be a phenomenon of oversupply, and the price of Tempering heat treatment resistance heating furnace will naturally be reduced.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

If there is a large demand for Tempering heat treatment resistance heating furnace in the market, the price of products will naturally be high. On the other hand, if the supply of this equipment exceeds demand, then manufacturers will have inventory accumulation. In order to dispose of these products as soon as possible, some manufacturers will sell them by lowering the price of products, so the price will be very low.

There are many manufacturers of products in Jinan, Shandong province, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Tempering heat treatment resistance heating furnace is naturally different.

Tempering heat treatment resistance heating furnace

Tempering heat treatment resistance heating furnacethe advantage is The maintenance cost is low, the Tempering heat treatment resistance heating furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.、The electrothermal conversion efficiency is high, and the Tempering heat treatment resistance heating furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.、Simple operation, relatively simple Tempering heat treatment resistance heating furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、The safety is high, and the Tempering heat treatment resistance heating furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Environmental protection, energy saving, no pollutants generated by fuel combustion, in line with environmental protection requirements; At the same time, due to high thermal efficiency, energy consumption is relatively low.,the main structure includes heating element, furnace chamber, furnace shell, Temperature control system and thermal insulation (material),This Tempering heat treatment resistance heating furnaceThe structural design is more advanced and reasonable.。

Related recommendation

-

What is a Multi tube roasting furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

台车式烘焙炉

2023-06-20 -

Introduction to Box type heat treatment furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Segmented gas trolley furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Regenerative burner penetrates forging heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Tempering and tempering heat treatment furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Heating furnace chamber type? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Electric heating furnace for annealing heat treatment, Trolley electric furnace advantages, characteristics and principles

2025-5-27 -

What is a Regenerative tube roasting furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Isothermal normalizing industrial furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27