Introduction to Tempering heat treatment resistance furnace and Trolley resistance heating furnace structure principle

Tempering heat treatment resistance furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,can be customized according to user's needs.。The following is to introduce the Tempering heat treatment resistance furnace:

1、Brief introduction of Tempering heat treatment resistance furnace

Tempering heat treatment resistance furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,It has a wide range of uses, and is often used inMelting of low melting point metal,braze welding,Metal heat treatment heating,Roasting and annealing of glass ceramics,Heating before metal forging and so on,the product looks beautiful.,it has the characteristics of Fast heating speed, energy-efficient, Accurate temperature control, Environmental protection and energy saving and Easy to control,Cheap and high quality。

Tempering heat treatment resistance furnace

2、Tempering heat treatment resistance furnace use

The purpose of Tempering heat treatment resistance furnace is introduced as follows:

- Metal melting and casting

- Ceramic and glass industries

- New material development

- Metal heat treatment

- powder metallurgy

Used for melting low melting point metals and alloys.

Used for baking and annealing of ceramics and glass.

Used for synthesis and heat treatment of special materials and new materials.

Such as quenching, normalizing, annealing, tempering, etc.

Used for sintering and heat treatment of powder.

Tempering heat treatment resistance furnace

3、Tempering heat treatment resistance furnace application

Tempering heat treatment resistance furnaces have the following purposes.

- Metal melting and casting

- Ceramic and glass industries

- Metal heat treatment

- powder metallurgy

- New material development

Used for melting low melting point metals and alloys.

Used for baking and annealing of ceramics and glass.

Such as quenching, normalizing, annealing, tempering, etc.

Used for sintering and heat treatment of powder.

Used for synthesis and heat treatment of special materials and new materials.

Tempering heat treatment resistance furnace

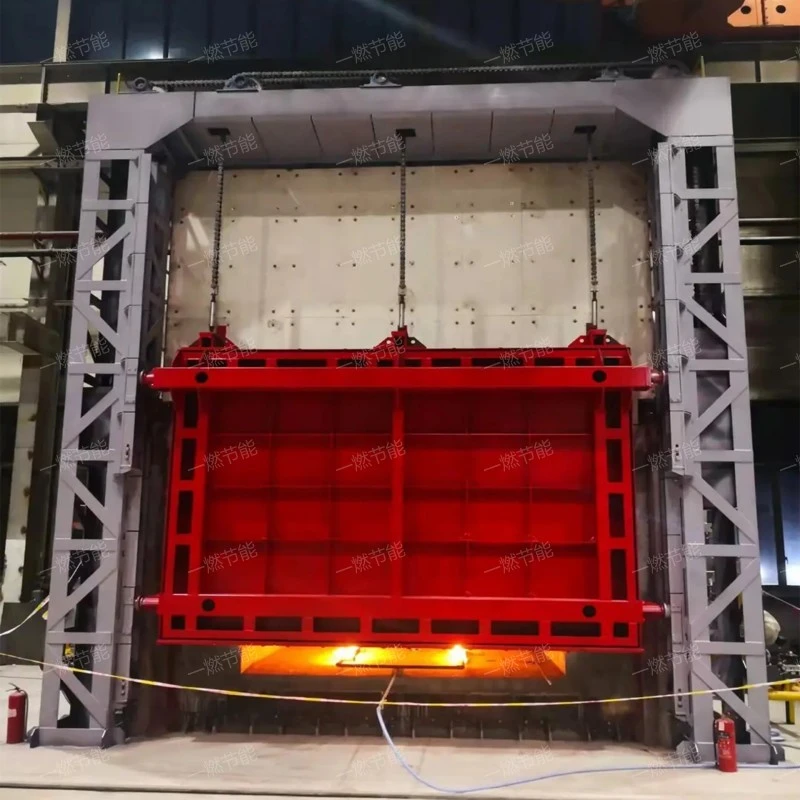

4、Tempering heat treatment resistance furnace work site real shot

A variety of series of Tempering heat treatment resistance furnace pictures are displayed, with exquisite design, reliable quality and trustworthiness.。

Tempering heat treatment resistance furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Introduction of advantages of Tempering heat treatment resistance furnace

Tempering heat treatment resistance furnaces have the following advantages.

- Strong customization

- Pollution-free discharge

- High security

- Environmental protection and energy saving

- Strong customization

The Tempering heat treatment resistance furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.

The Tempering heat treatment resistance furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.

The Tempering heat treatment resistance furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.

No pollutants generated by fuel combustion, meeting the requirements of environmental protection; At the same time, due to high thermal efficiency, energy consumption is relatively low.

The Tempering heat treatment resistance furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.

Tempering heat treatment resistance furnace

6、Tempering heat treatment resistance furnace quotation

The Tempering heat treatment resistance furnace price is introduced as follows:

- Product technology

- Product configuration difference

- Model type

- manufacturing cost

- Company size

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The difference in Tempering heat treatment resistance furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Because there are many specifications and models of Tempering heat treatment resistance furnace, the quotations of Tempering heat treatment resistance furnace with different specifications and models are different.

The production cost is mainly the purchase of raw materials. One-combustion energy saving attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, One-combustion energy saving strives to reduce the input cost of products, and customers are very satisfied with this.

At present, there are many manufacturers of products on the market, some of which belong to direct selling manufacturers and some belong to middlemen. Direct selling manufacturers will cost less than middlemen, so the quotation for products will be lower. Therefore, it is recommended that customers buy products from direct selling manufacturers of Tempering heat treatment resistance furnace. In addition, even direct selling manufacturers have different capital status, strength level and technology, and the quotation for Tempering heat treatment resistance furnace will be different.

Tempering heat treatment resistance furnace

Tempering heat treatment resistance furnaceThe structural design is simple, novel and special.,it is mainly composed of furnace shell, Temperature control system, furnace chamber, heating element and furnace shell,is an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,is a Tempering heat treatment resistance furnace。

Related recommendation

-

What is a Automatic temperature regulating box type heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Gas storage box type heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Dual car quenching furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Continuous bright quenching furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Roller bottom heat treatment heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Split type well tube furnace and forging furnace structure principle

2025-5-27 -

Introduction to Roll type heat treatment furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Double car mold shell roasting furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Segmented gas trolley furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Gas trolley forging furnace? Introduction to the principle of forging furnace structure

2025-5-27