Introduction to Tempering resistance furnace and Trolley resistance heating furnace working principle

Tempering resistance furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.。The following is to introduce the Tempering resistance furnace:

1、Brief introduction of Tempering resistance furnace

Tempering resistance furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,it has the characteristics of Electrothermal conversion efficiency, Long service life, Fast heating speed, Easy to operate and maintain. and High flexibility,be loved by our customers.。

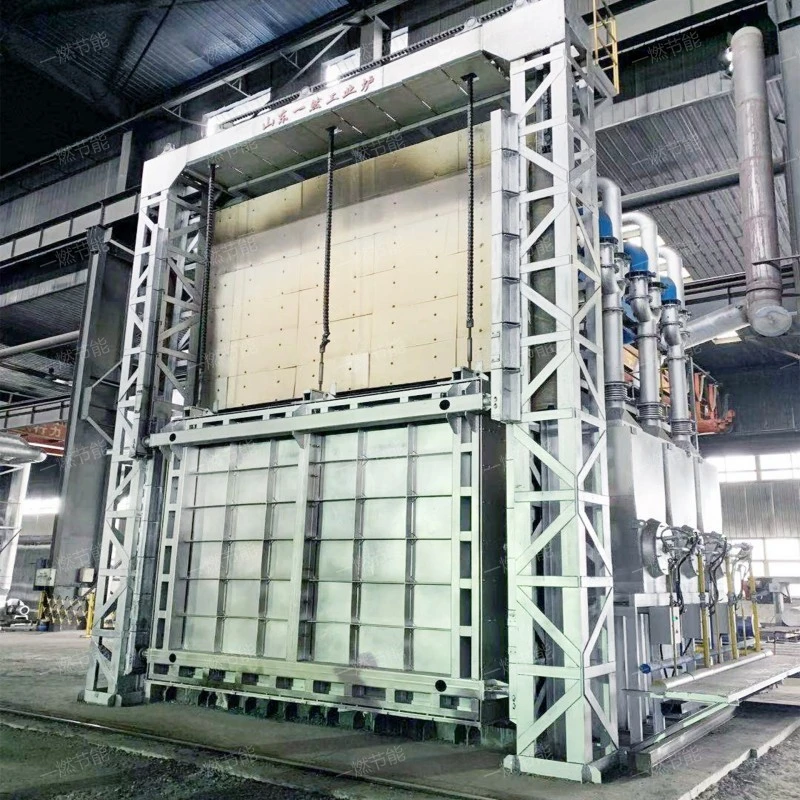

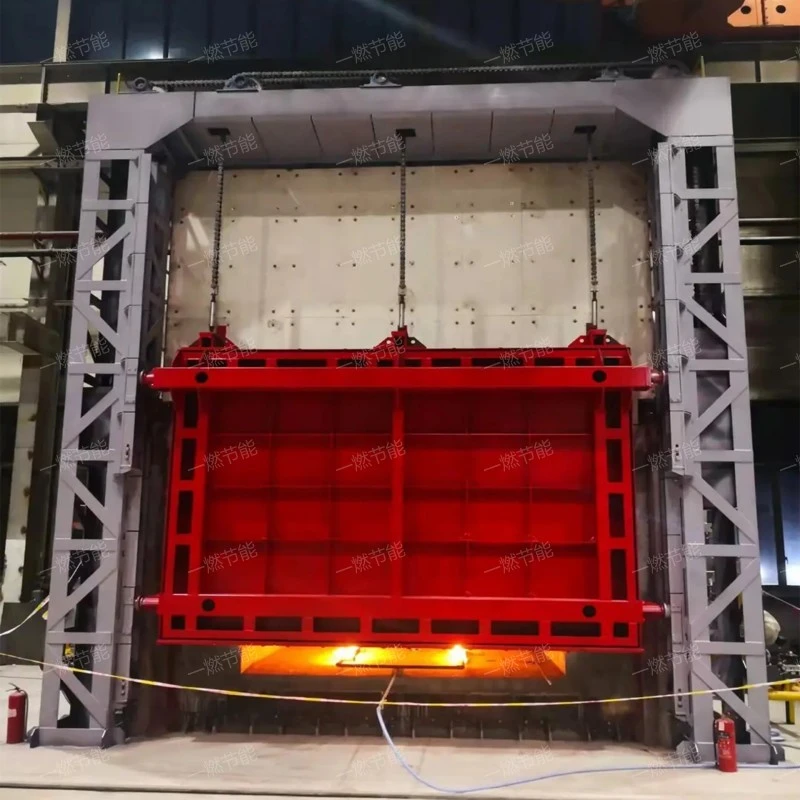

Tempering resistance furnace

2、Tempering resistance furnace advantage

The advantages of Tempering resistance furnace are as follows:

- High thermal efficiency

- Easy to control

- Low maintenance cost

- High security

- Wide application range

High thermal efficiency, higher than traditional heating equipment such as flame furnace.

The furnace temperature is controlled accurately, which is convenient for automatic control.

The structure of the Tempering resistance furnace is relatively simple, and it is convenient to maintain, and the failure rate is relatively low, which helps to reduce the maintenance cost.

The Tempering resistance furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.

Tempering resistance furnaces are suitable for heating workpieces of various shapes and sizes, and can meet the heating needs of different industries and processes.

Tempering resistance furnace

3、Tempering resistance furnace structure

The Tempering resistance furnace structure is introduced as follows:

- furnace shell

- heating element

- control system

- furnace body

- Temperature control system

The furnace shell is usually made of steel plate for protection.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

The control system is the command center of the Tempering resistance furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

Tempering resistance furnace

4、Tempering resistance furnace display

Its appearance design is exquisite and elegant. The following is a high-definition picture of the factory for One-combustion energy saving's customers to choose and buy. You can contact online customer service at any time, make an appointment to visit the factory and take a shuttle bus from One-combustion energy saving.。

Tempering resistance furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Tempering resistance furnace price

The Tempering resistance furnace price is introduced as follows:

- Manufacturer's strength

- Brand strength

- Model size

- product costs

- product quality

One-combustion energy saving's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

At present, there are various brands of Tempering resistance furnace in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Tempering resistance furnace are different.

The same product, even with different specifications and models and different configurations, has different costs, so the price will be different.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Tempering resistance furnace just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

The condition of the product itself has a great influence on its price, and the cost of the product with excellent quality is higher, which will lead to the increase of the selling price of the product. Therefore, this is an important factor that causes the price fluctuation and change of the Tempering resistance furnace.

Tempering resistance furnace

6、Why choose One-combustion energy saving?

Choosing a suitable Tempering resistance furnace manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Tempering resistance furnace products that meet the demand and have good cost performance.。

One-combustion energy saving

Tempering resistance furnaceFast heating, the Tempering resistance furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, the heating Tempering resistance furnace is directly heated, and the current directly passes through the material, so the heating speed is faster.、The temperature control precision is high, and the Tempering resistance furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.、The temperature uniformity is good, and the temperature distribution in the Tempering resistance furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、The maintenance cost is low, the Tempering resistance furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.、Wide application range, the Tempering resistance furnace is suitable for heating workpieces of various shapes and sizes, and can meet the heating requirements of different industries and processes.,is a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.。

Related recommendation

-

Introduction to Double chamber forging furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Mobile natural gas trolley furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

What is a Automatic temperature control tube furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Natural gas thermal storage tubular roaster, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Rotary annealing industrial furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Aluminum alloy casting electric furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

What is a walking beam heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Aluminum coil heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Well type forging furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Chain type annealing furnace? Introduction to the principle of forging furnace structure

2025-5-27